Can I use the same indenter for different hardness tests?

Nanoindentation

Technical Notes

Can I use the same indenter for different hardness tests?| Micro Material Testing Instruments

Some indenters are specific to certain tests due to their design and the test's requirements. For example, a diamond pyramid indenter is used in both Vickers and Knoop tests, but the test method and application differ. It's essential to use the indenter specified for each test to ensure accurate results.

For immediate assistance, you can reach us by phone or email. Our team is always happy to answer any queries you have, big or small. Check our contact details below:

- Phone: +441978261615

- Email: info@micromaterials.co.uk

- Office Address: Willow House • Yale Business Village • Ellice Way • Wrexham • LL13 7YL • United Kingdom

- Business Hours : We operate from 08:30am to 05:00pm Monday through Friday, and we aim to respond to all messages within 24 hours.

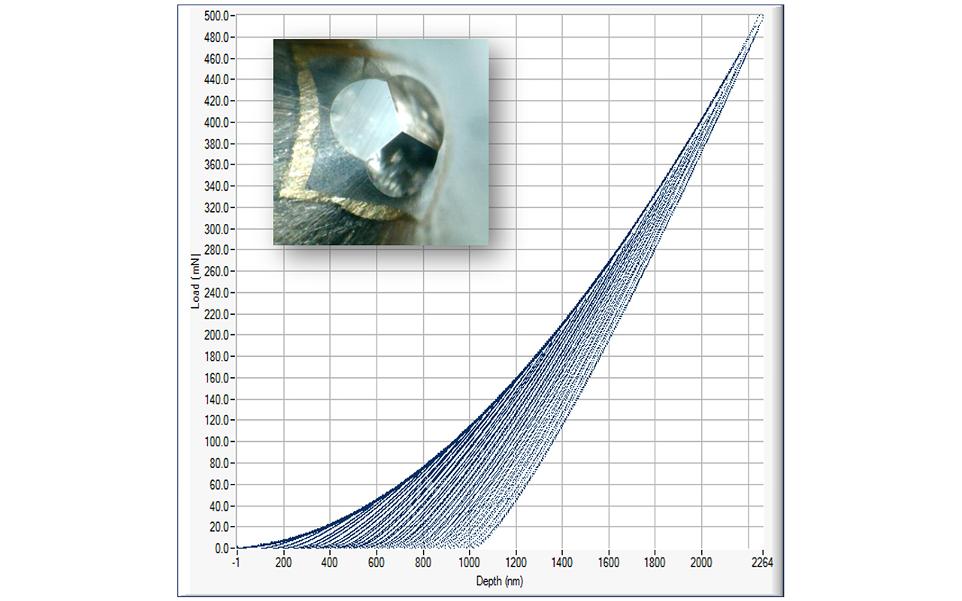

100 nanoindentation measurements on a fused silica reference sample.

Most nanoindentation work for measurement of hardness and elastic modulus is performed using a three sided “Berkovich” indenter.

Many other indenter geometries are available for different test types.

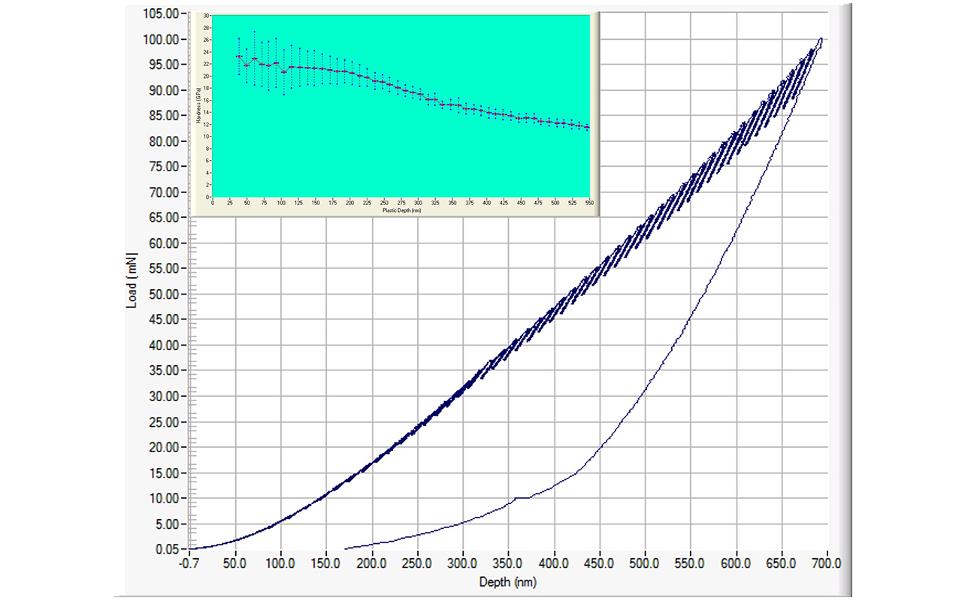

The load-partial unload (multi-cycle) indentation technique allows for the rapid profiling of hardness and elastic modulus variation as a function of depth.

In this example, a 50-cycle test from 5 mN to 100 mN was performed on a 2 µm DLC coating on silicon. The inset plot shows decreasing hardness as the influence of the softer silicon substrate increases with increasing indentation depth.

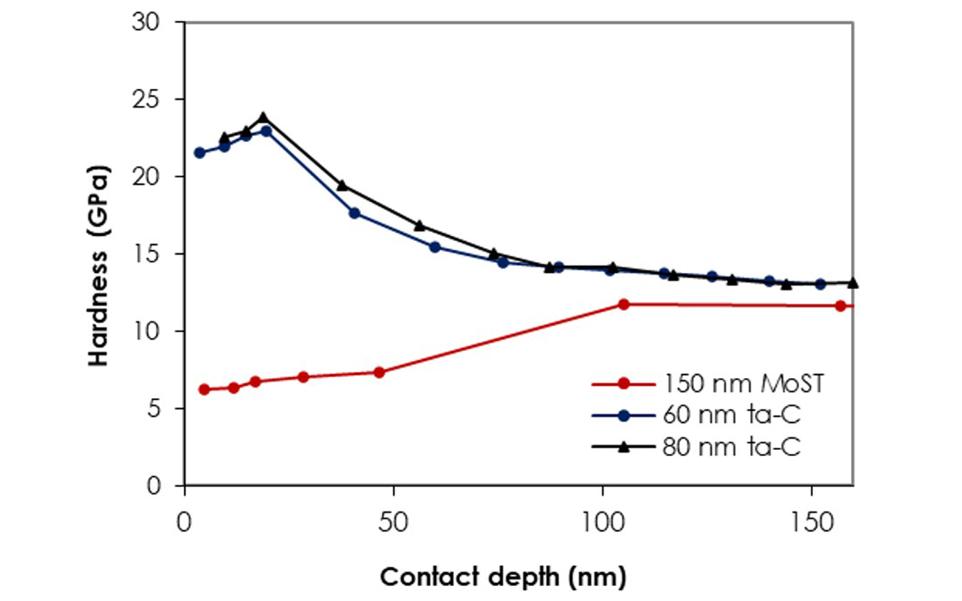

Very low noise floor and thermal drift rates mean that high measurement accuracy is retained down to very small contact depths.

Here three samples with low friction coatings have been profiled down to contact depths of 5 nm.

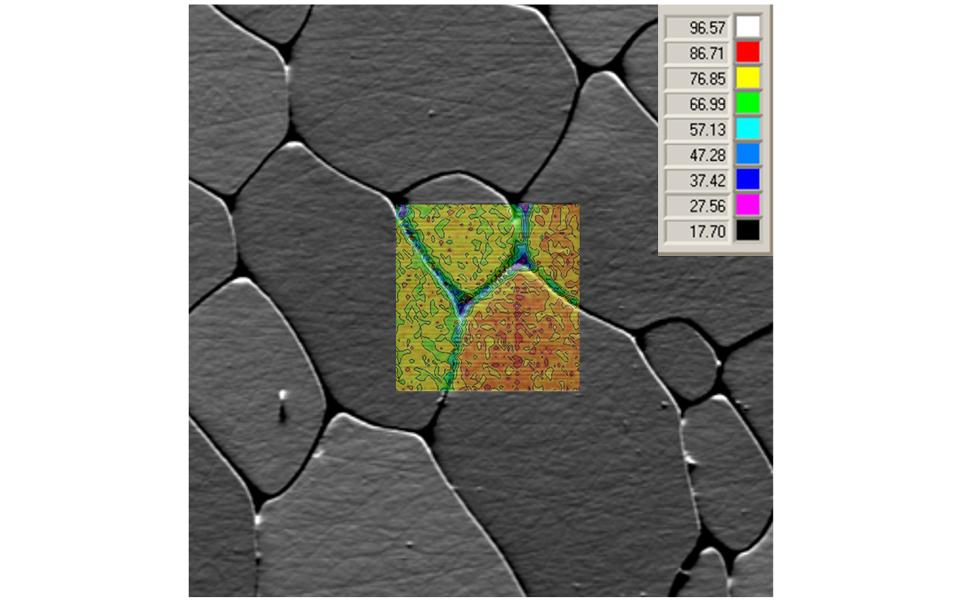

Mechanical properties may be mapped across areas as small as 1μm² up to several cm².

In this case the elastic modulus of four calcite crystals of a Pinna Nobilis shell have been mapped over and area of 45 x 45 µm. The crystals of interest were first identified using EBSD, the sample was then transferred to the NanoTest Vantage and the region of interest targeted using the instrument’s integrated optical microscope.

Once tests are complete a full statistical analysis of the results is possible within the NanoTest™ Vantage™ software.

A wide range of other tests are also possible using instrumented indentation, these include:

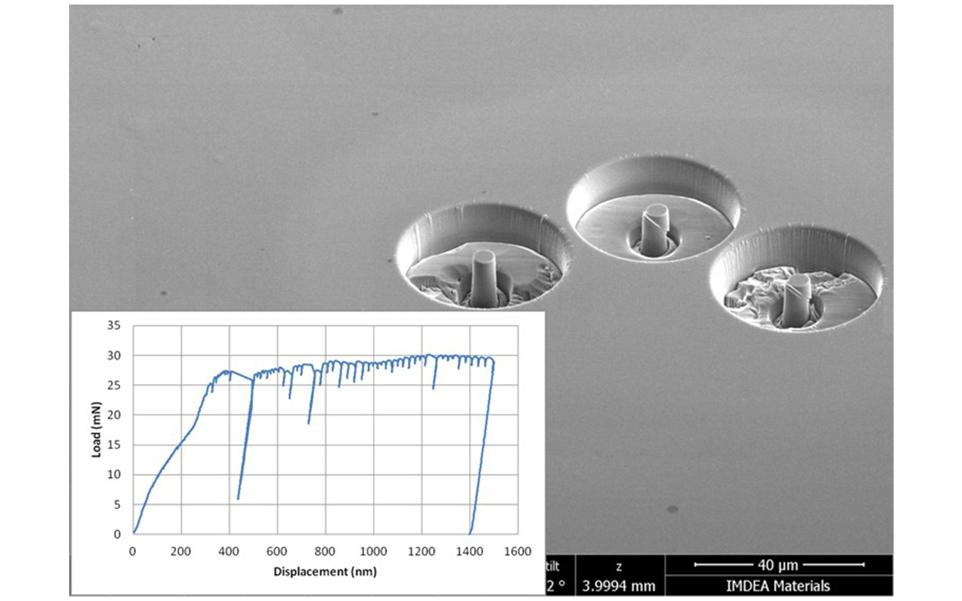

Micro-pillar compression

Micro-cantilever bend tests

Fibre push-out tests

Adhesion tests (pull-off force)

Particulate compression tests

This example demonstrates micro-pillar compression of an IN718 superalloy. Tests were performed in displacement rate controlled mode and load-drop events are seen in response to transient deformation events in the pillar.

High load testing to 30N

Technical Notes

Computational modelling

Technical Notes

Acoustic emission

Technical Notes

Electrical contact resistance

Technical Notes

Dynamic Mechanical Compliance testing

Technical Notes

Multiscale mechanical property mapping

Application Notes

Indentation creep

Application Notes

High temperature creep resistance

Application Notes

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.