In-Depth Book Chapters on Nanomechanics, Nanoindentation, and Advanced Coatings

Comprehensive Insights into Nanoindentation, Tribology, and Coating Technologies

Our applications team, led by Professor Ben Beake, have extensive experience in the field of nanomechanics. Their expertise is captured in several specialised book chapters co-authored by them. Abstracts of these highly informative chapters are given below.

Protective Thin Coatings Technology

Editor: S Zhang, J-M Ting and W-Y Wu

Publisher: CRC Press (August 2021)

ISBN: 978100 3088349

Book Summary

Hard or protective coatings are widely used in conventional and modern industries and will continue to play a key role in future manufacturing, especially in the micro and nano areas. Protective Thin Coatings Technology highlights the developments and advances in the preparation, characterization, and applications of protective micro-/nanoscaled films and coatings.

Key chapter: Chapter 4 “Integrated nanomechanical characterisation of hard coatings”, BD Beake, VM Vishnyakov, TW Liskiewicz, pp95-140.

Chapter Abstract:

In collaboration with Prof Tomasz Liskiewicz at MMU and Prof Vlad Vishnyakov at Huddersfield on combining advanced experimental techniques in the NanoTest with simulated stress distributions to better understand coating performance in demanding tribological applications and to design coating systems for improved wear resistance:-

In the chapter we show how detailed simulated stress distributions enable room and high temperature microtribological data to be interpreted more effectively providing mechanistic information which can be the key to unlocking exactly where and why coatings systems fail, and then to designing coatings with improved performance.

Applied Nanoindentation in Advanced Materials

Editor: Dr A Tiwari

Publisher: Wiley

ISBN: 978-1-119-08449-5

Book Summary

Comprehensive, self-contained reference covering applied aspects of nanoindentation in advanced materials.

Key chapter: Nanomechanical characterization of carbon films

B D Beake & T W Liskiewicz

Chapter Abstract:

Accurate nanomechanical characterisation is a critical step in the efficient optimisation of DLC films for demanding applications. In this chapter the key factors that are required for accurate hardness and elastic modulus determination are highlighted and the further complications that arise when measuring on ultra-thin DLC films. In addition to hardness and modulus nanoindentation can provide information about film plasticity and its correlation to H/E and, depending on film composition and indenter geometry, cracking may also occur during loading and the role of substrate deformation is discussed.

For more complete characterisation the results of the nanoindentation tests are combined with additional nanomechanical and nano-tribological test capability available in the NanoTest system, namely nano-scratch, nano-impact and nano-fretting. These tests provide complementary information about the durability of DLC films in these more complex mechanical loading situations. By combining the results of all the nanomechanical tests performed with the NanoTest system it is clear that (i) DLC films show strong load dependence in their properties with extensive fracture at high load (ii) there is an optimum H/E which is related to the contact conditions in the actual application (iii) a multi-technique nanomechanical characterisation provides more useful data for design and coating system optimisation than nano-indentation alone.

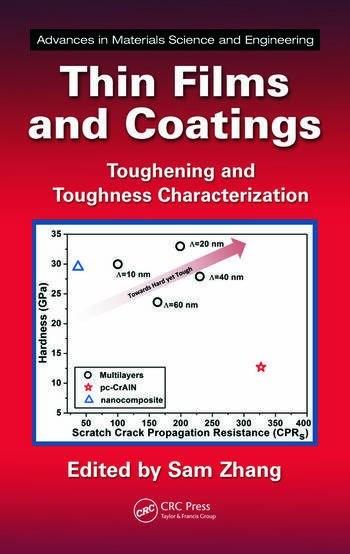

Thin Films and Coatings: Toughening and Toughness Characterisation

Editor: S Zhang

Publisher: CRC Press (July 2015)

ISBN: 978148 2222906

Book Summary

Thin Films and Coatings: Toughening and Toughness Characterization captures the latest developments in the toughening of hard coatings and in the measurement of the toughness of thin films and coatings. Presents the current status of hard-yet-tough ceramic coatings.

- Reviews various toughness evaluation methods for films and hard coatings

- Explores the toughness and toughening mechanisms of porous thin films and laser-treated surfaces

- Examines adhesions of the film/substrate interface and the characterization of coating adhesion strength

- Discusses nanoindentation determination of fracture toughness, resistance to cracking, and sliding contact fracture phenomena

Key chapter: Chapter 2: Toughness Evaluation of Thin Hard Coatings and Films

X Zhang, S Zhang & B D Beake

Chapter Abstract:

A wide range of qualitative and quantitative methods for characterisation of the toughness of thin films and hard coatings are reviewed including indentation plasticity, scratch toughness, nano-impact, indentation-induced cracking and micro-tensile testing of standalone thing films.

In particular nano-impact extends the range of nanomechanical test techniques to much higher strain rates than are possible in standard nanoindentation. Repetitive high-strain contact allows the durability of coatings under intermittent highly loaded contact to be determined and the fatigue fracture resistance determined in the nano-impact test shows a very high level of correlation with coating performance in these types of contact situations —such as hard coatings for cutting tools or TBCs subject due to erosive impacts in jet engines — due to the closer simulation than in quasi-static tests.

Click here to buy this book

Protective Thin Coatings Technology

Editor: S Zhang

Publisher: CRC Press (July 2015)

ISBN: 978148 2222906

Book Summary

Hard or protective coatings are widely used in conventional and modern industries and will continue to play a key role in future manufacturing, especially in the micro and nano areas. Protective Thin Coatings Technology highlights the developments and advances in the preparation, characterization, and applications of protective micro-/nanoscaled films and coatings.

Key chapter: Chapter 4 “Integrated nanomechanical characterisation of hard coatings”, BD Beake, VM Vishnyakov, TW Liskiewicz, pp95-140.

Chapter Abstract:

In collaboration with Prof Tomasz Liskiewicz at MMU and Prof Vlad Vishnyakov at Huddersfield on combining advanced experimental techniques in the NanoTest with simulated stress distributions to better understand coating performance in demanding tribological applications and to design coating systems for improved wear resistance:-

In the chapter we show how detailed simulated stress distributions enable room and high temperature microtribological data to be interpreted more effectively providing mechanistic information which can be the key to unlocking exactly where and why coatings systems fail, and then to designing coatings with improved performance.

Click here to buy this book

Multifunctional materials for tribological applications

Editor: Prof Robert Wood

Publisher: Pan Stanford Publishing

ISBN: 9789814463904

Book Summary

This book covers the increasingly important aspect for engineering surfaces to be multifunctional with a focus on tribological applications. It captures the state of the art regarding the emerging needs for multifunctional surface design for controlling wear, friction, and corrosion, as well as having decorative, self-healing, and/or self-sensing capabilities. It focuses on coatings and materials that include CVD diamond, diamond-like carbon, and multi-layered and functionally graded systems for a range of engineering applications including machine tools, orthopaedic joints, aero-engines/gas turbines, automotive engines, glass windows and walls, and offshore and marine sectors.

Key chapter: High temperature coatings

B D Beake, GS Fox-Rabinovich

Chapter Abstract:

To achieve long tool life in high-speed machining of hard-to-cut materials PVD coatings need to be multifunctional and display several interlinked characteristics to minimise wear. This chapter introduces the use of advanced nanomechanical testing with the NanoTest as a tool in coating optimisation for durability under the severe conditions of metal cutting.

It focuses on high temperature nanoindentation testing to 750 ºC and repetitive nano-impact testing of coated cutting tools. It is shown that different cutting conditions require different mechanical properties. The NanoTest data is used to develop design rules for the optimum coating mechanical properties in interrupted and continuous cutting tests with advanced monolayer and multilayer high Al-fraction nitride coatings.

Nanomechanical analysis of high performance materials

Editor: Dr Atul Tiwari

Publisher: Springer

ISBN: 978-94-007-6919-9

Book Summary

This book is intended for researchers who are interested in investigating the nano-mechanical properties of materials using advanced instrumentation techniques.

Key chapter: Environmental nanomechanical testing of polymers and nanocomposites. Prof Jian Chen, BD Beake, Prof Hanshan Dong, Gerard A Bell

Chapter Abstract:

The ever-increasing popularity of nanomechanical testing is being accompanied by the development of more and more novel test techniques to work in increasingly environmentally challenging test conditions. Considerable progress has been made and reliable mechanical properties of materials can now be obtained at a range of temperatures and surrounding media, greatly aiding development for operating under these environmental conditions. In this chapter, several of these developments are reviewed, focusing on their use in the non-ambient nanomechanical testing of polymers and nanocomposites.

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.