Dynamic Mechanical Compliance Testing (DMCT) for Precise Material Property Analysis

Applications of DMCT in Advanced Material Research

The Dynamic mechanical compliance testing (DMCT) module is used for (i) depth profiling of mechanical properties (hardness, elastic modulus, H/E, contact stiffness) using the continuous stiffness approach, and (ii) viscoelastic property measurements (storage modulus, loss modulus, tan delta) at chosen frequencies and test temperatures.

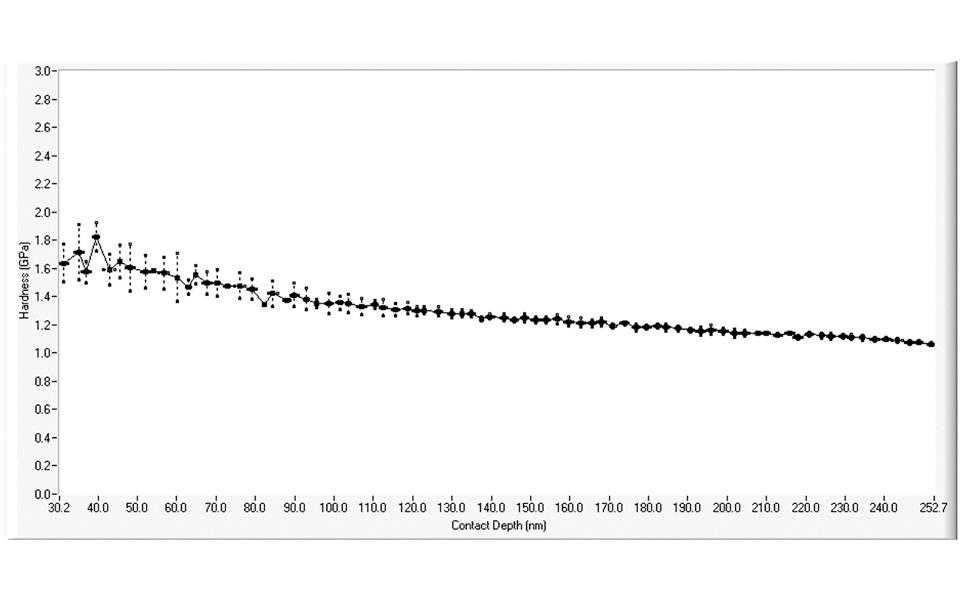

Literature reports have highlighted difficulties in using the conventional continuous stiffness technique to make meaningful measurements at low depths on soft metals with high E/H ratios, such as copper or aluminium, which are subject to probe bouncing and plasticity errors. In contrast, the new approach taken in the NanoTest DMCT module has produced significantly improved results, with the problem of the probe bouncing on the surface at low depth effectively suppressed, thus avoiding the anomalous low-depth data.

Depth dependence of hardness for Cu(100) single crystal from DMCT showing a typical indentation size effect – note the absence of any anomalous results or data variability at low depths. The data show mean values from 3 repeat tests.

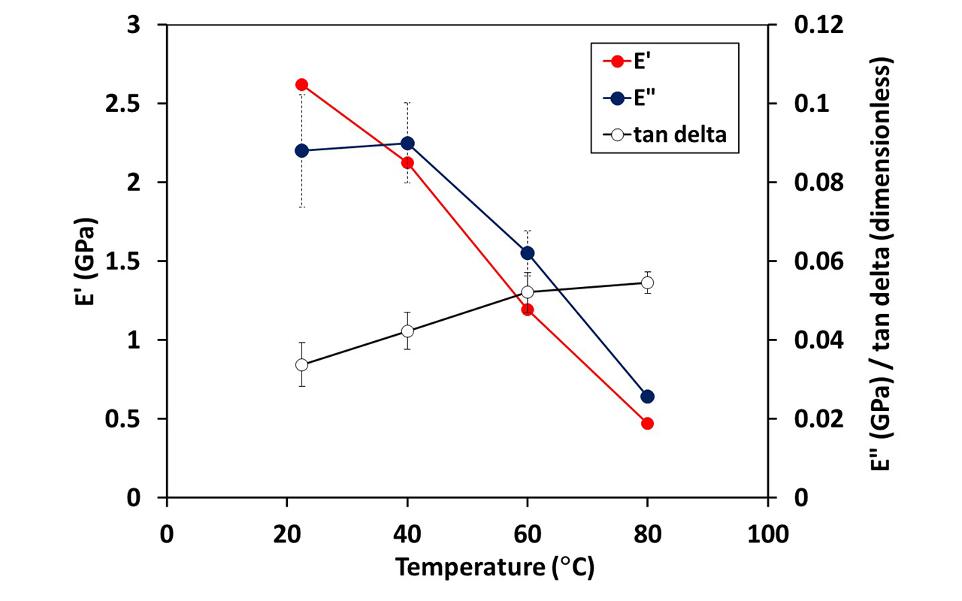

Viscoelastic properties can be measured

The DMCT module allows measurements of the viscoelastic properties (loss and storage moduli, tan delta) of viscoelastic materials and their dependence on test temperature.

Variation in loss modulus, storage modulus and tan delta with temperature for a viscoelastic fluoropolymer nanocomposite

The maximum test frequency is >300 Hz and the experiments can be run as frequency sweeps at each temperature.

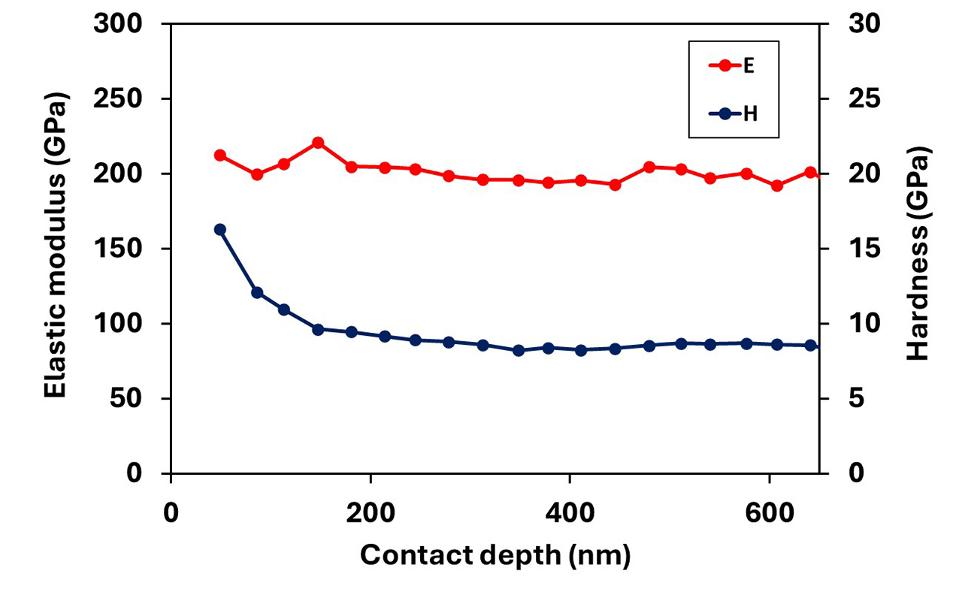

Tests with the DMCT module can be performed at elevated temperature, for example to study (i) influence of temperature on mechanical properties of coated surfaces (ii) temperature-dependence of indentation size effects in metallic materials.

Hardness and elastic modulus vs. depth at 200 C in a high carbon martensitic steel from a DMCT experiment to 100 mN with a cBN Berkovich indenter

At 200 C, this sample still shows a size effect in hardness but not in elastic modulus, which remains constant throughout the depth range.

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.