Electrochemical Cell Module with Potentiostat/Galvanostat for Precise Control

Applications in Simulated Environments

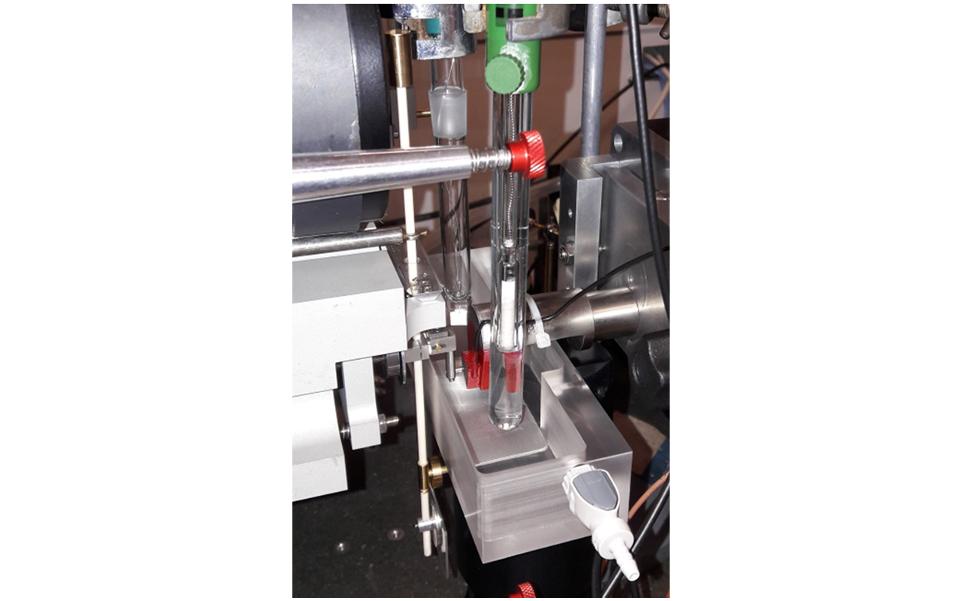

The Electrochemical Cell Module includes a potentiostat/galvanostat to precisely control an electrochemical cell where the sample is the working electrode. Control can be either constant potential or constant current mode. For simulation of a wide range of real-world conditions including sub-sea and in-vivo. Tribo-corrosion experiments can also be carried out.

In the electrochemical cell the indenter and the sample are both electrically isolated from the instrument. The cell is set up with a platinium counter electrode, Ag/AgCl reference probe to provide feedback for potentiostat and the sample acting as the working electrode.

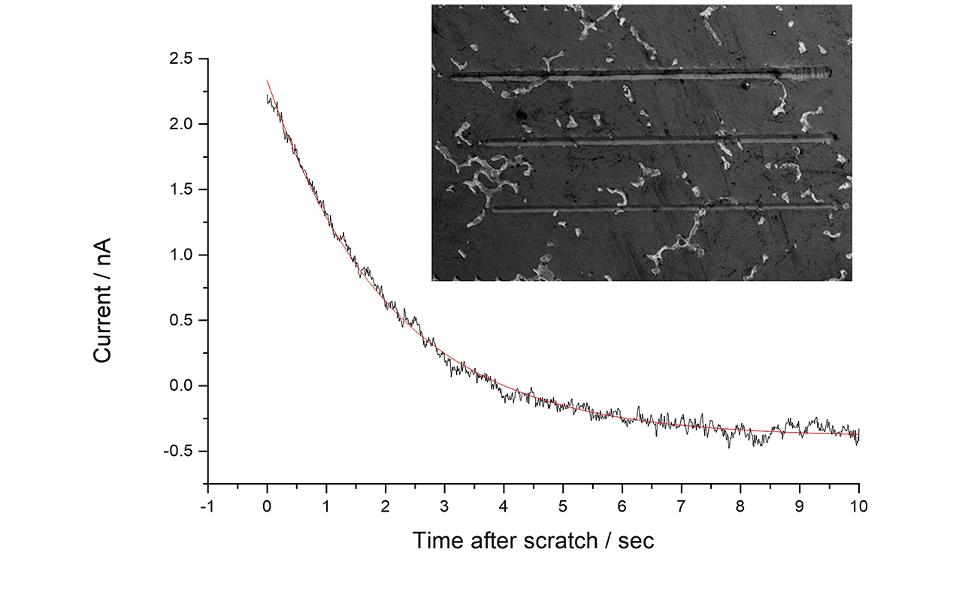

To simulate the wear damage caused by single abrasive particles trapped between the surfaces of CoCrMo replacement hip joints, nano-scratch tests with simultaneous electrochemical measurements have been performed on CoCrMo alloy samples in simulated body fluid.

Nano-scratches cause an increase in electrical current due to rupture (depassivation) of the native oxide film on the CoCrMo alloy. The subsequent re-passivation kinetics are accurately modelled with a simple first-order decay process.

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.