Low-Temperature Nanomechanical Testing Solutions

Cold stage

Technical Notes

Applications of Low-Temperature Nanomechanical Testing

Many materials, particularly polymeric materials, show interesting transitions in mechanical properties and creep behaviour at sub-ambient temperatures. Understanding this behaviour is critical to exploring the use of these materials in extreme environments.

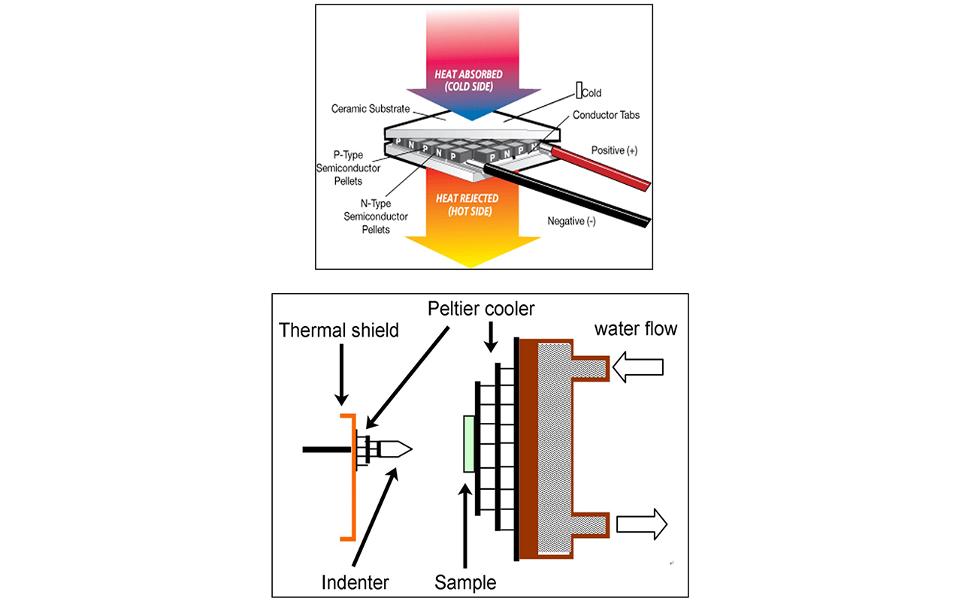

The cold stage from Micro Materials allows the user to perform nanoindentation, nano-scratch & wear and nano-impact tests with the indenter and sample at sub-ambient temperatures; down to -20 °C on the NanoTest™ Vantage™, and -40 °C on the NanoTest™ Xtreme™

The cold stage uses precise Peltier cooling to cool both the sample stage and indenter to the required test temperature. Proprietary techniques then ensure isothermal contact between the indenter and the sample before the test starts.

Experiments take place in a nitrogen purged atmosphere (Vantage™) or high vacuum (Xtreme™) to stop the formation of ice crystals in the test region. Testing can then be performed at any temperature from room temperature down to -20 ºC (Vantage™) or -40 ºC (Xtreme™).

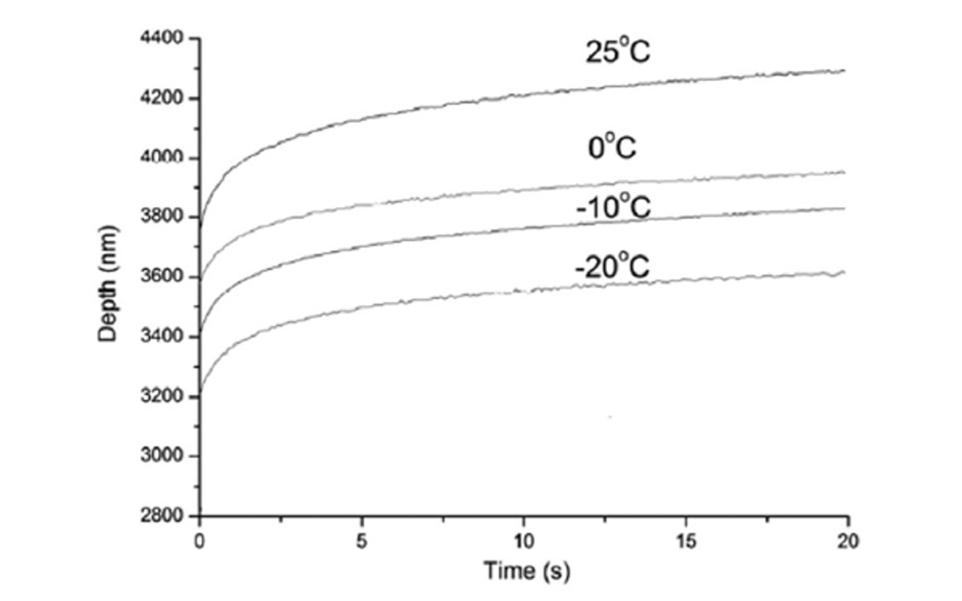

Effect of low temperature on creep behaviour

A key area of interest in polymer research is the effect of low temperatures on the creep behaviour of polymer films.

The stability of the NanoTest™ at sub-ambient temperatures allows direct assessment of the creep behaviour even at the lowest temperatures.

The example shown here demonstrates difference in creep behaviour of a polymeric sample – as the temperature is lowered, the creep rate reduces due to the reduction in viscoelastic behaviour of the sample.

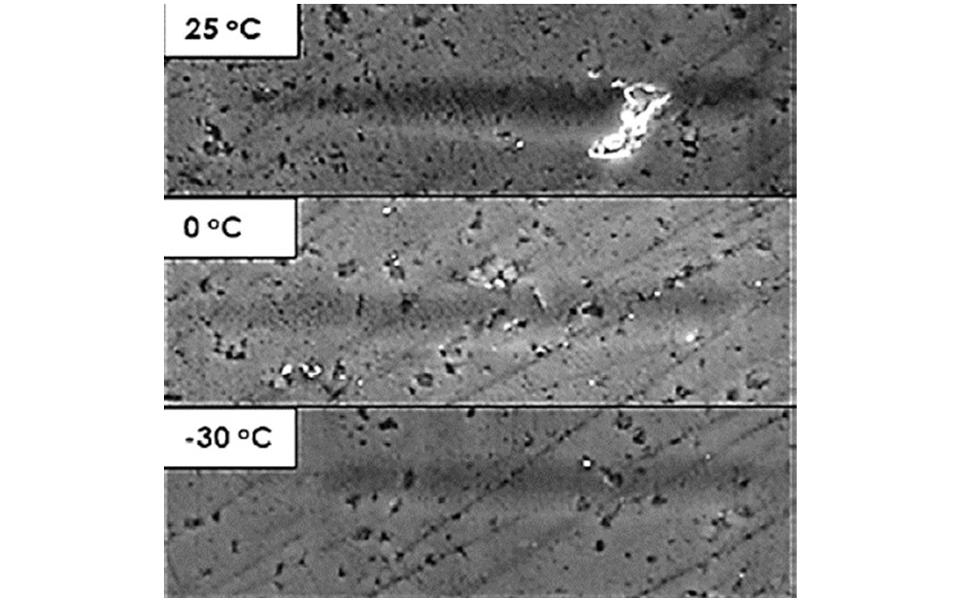

Combining cold stage and scratch capabilities

It is also possible to directly assess material wear behaviour by combining the cold stage and scratch test capabilities of the NanoTest™. This has been done in the example shown where ramped load scratch tests have been performed on a composite DLC coating at different temperatures.

Interestingly, the volume of material removed from the surface reduces as the sample is cooled. The wear track is significantly shallower at sub-ambient temperatures than at room temperature. The coating is also more resistant to cracking at lower temperatures.

Nanoindentation

Technical Notes

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.