Tribology

Understanding Friction and Wear in Materials

Scratch and friction

Technical Notes

Introduction to Tribology Testing

Taking advantage of the high lateral rigidity, high sensitivity and high stability of the Vantage™ system Micro Materials have developed a range of nanotribological modules including scratch, fretting and NanoTriboTest (reciprocating) tests and combined these with additional multi-sensing capability.

As single-asperity contacts, nanotribological tests provide unique insights into the roles of test severity and type, surface topography and mechanical properties on friction and wear. They enable individual mechanisms to be isolated and studied in-depth improving fundamental understanding of friction and wear mechanisms.

The full load range is available in all the tribology modules allowing tests to be performed over a wide range of contact pressures by changing the load and probe geometry.

This allows lab-scale replication of the widest possible range of real-world contact scenarios.

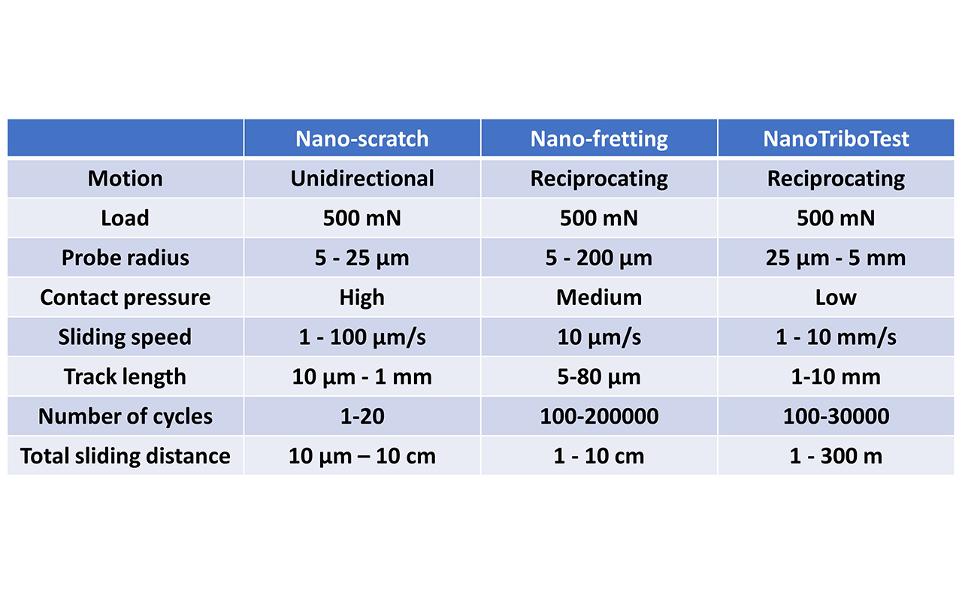

Typical conditions are shown in the table.

Reciprocating friction and wear

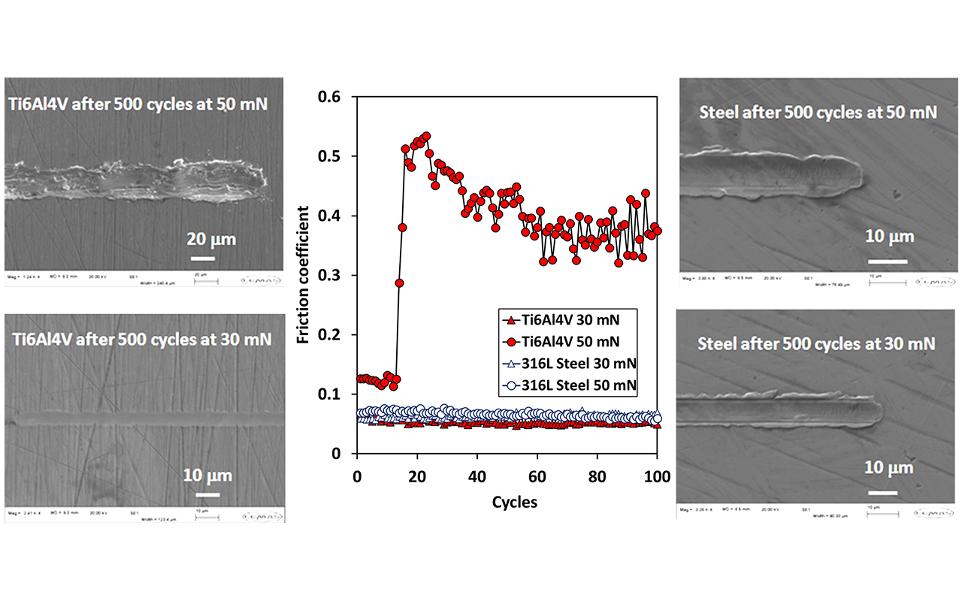

Reciprocating friction and wear testing with the NanoTriboTest has revealed extremely load- and cycle- dependent friction and wear behaviour on Ti6Al4V which was not found for 316L stainless steel.

At 50 mN the passive oxide on Ti6Al4V breaks with multi-cycling causing the underlying alloy to be exposed with dramatic increase in friction and reduction in wear resistance.

Nano-fretting

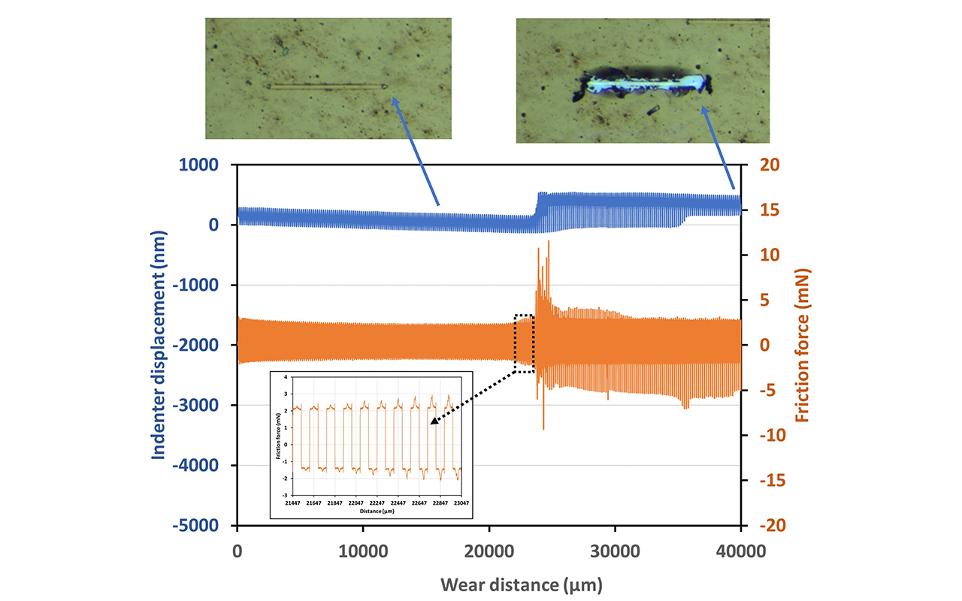

Nano-fretting experiments reveal how coatings degrade and ultimately fail cycle-by-cycle.

Clear failure during a 250-cycle test on a TiN coating on Si with 25 mN normal load, 5 µm radius diamond indenter, 80 µm track length, 10 µm/s velocity.

Includes comprehensive software package for visualizing how friction and energy dissipation change with sliding distance and wear.

References:

1. Contact size effects on the friction and wear of amorphous carbon films, BD Beake, SJ McMaster, TW Liskiewicz, Applied Surface Science Advances 9 (2022) 100248 (19pp).

2. Friction and electrical contact resistance in reciprocating nano-scale wear testing of metallic materials, BD Beake, AJ Harris, TW Liskiewicz, J Wagner, SJ McMaster, SR Goodes, A Neville, L Zhang, Wear, 474-475 (2021) 203886.

NanoTriboTest

Technical Notes

Nano-fretting

Technical Notes

Nano-impact and fatigue

Technical Notes

Acoustic emission

Technical Notes

Wear resistant coatings

Application Notes

High temperature micro-scratch and impact

Application Notes

NanoTriboTest Publication Precis

Application Notes

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.