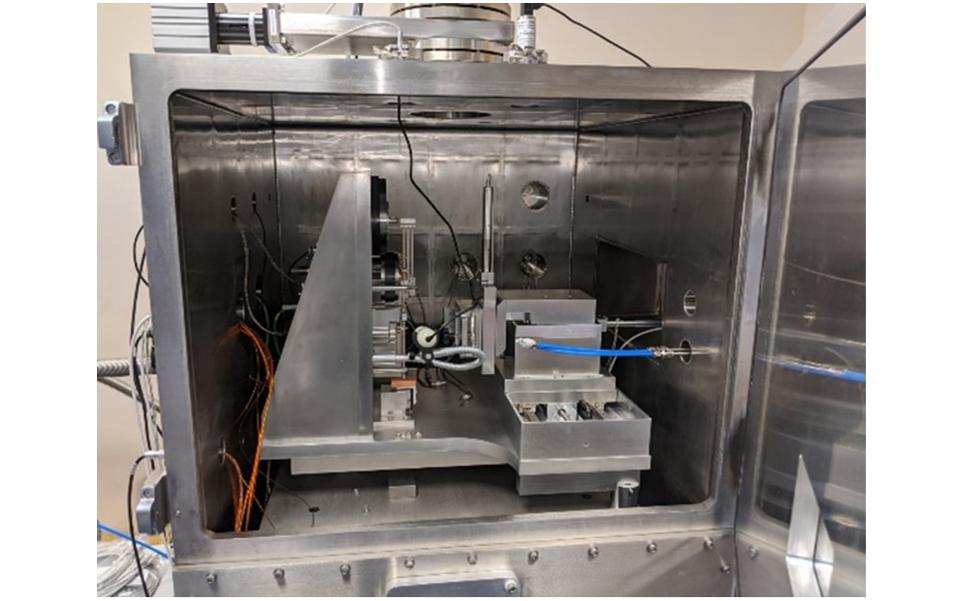

NanoTest™ Xtreme™

Advanced High Vacuum Nanomechanical Testing Platform

High Vacuum Environment for Precise High-Temperature Nanomechanical Testing

The Xtreme™ is the most flexible multi-load-range, multi-test-technique high vacuum mechanical testing platform available. It builds on the class leading high temperature performance of the Vantage™ by integrating with a high vacuum testing environment.

The vacuum equipment utilises a turbomolecular pump, which allows a high vacuum to be attained. The Xtreme™ design allows all experiments to be run under high vacuum with all pumps running.

The Xtreme™ may also be used as a regular ambient instrument, by simply not running the pumping system.

The NanoTest™ Xtreme™ retains all the flexibility of the Vantage™ combined with appropriate design modifications for vacuum compatibility.

Access to the instrument is unobstructed, making it easy to exchange indenters, mount samples and swap test modes. As with the Vantage™, the Xtreme™ can be configured with one or multiple loading heads and either a single or multiple objective lens optical microscope. Operational vacuum levels are reached within 30 minutes of pumping time.

Ultra-low thermal drift rates are maintained throughout the operational temperature range.

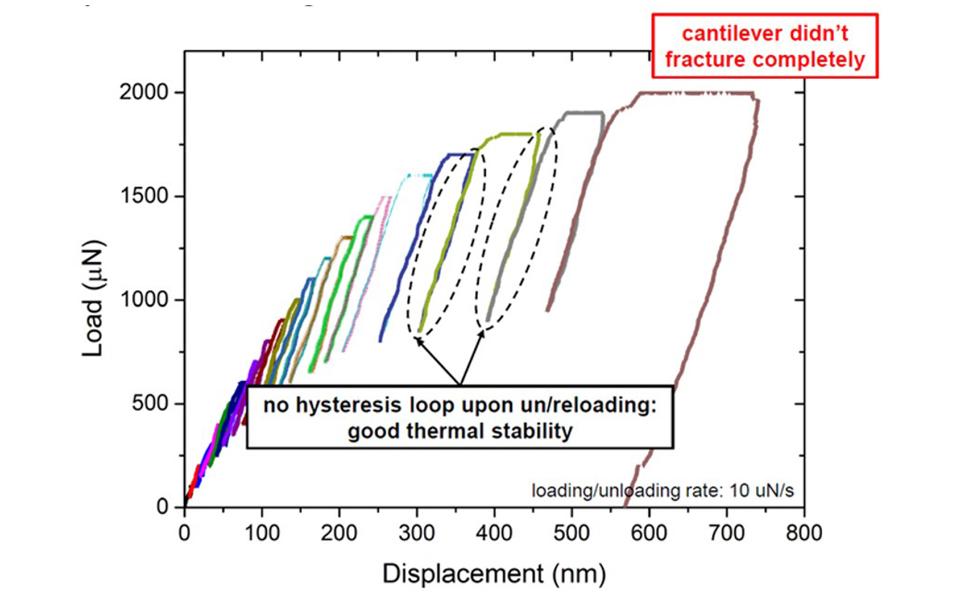

A micro-cantilever sample has been put through a multi-cycle flexural test at 700 °C to drive stable crack growth through a grain boundary in a W 1%Ta alloy. To drive the slow crack growth, an intentionally low loading / unloading rate of 10 µN/s was used and the total contact time of the test was 2 hours.

The primary purpose of the vacuum environment of the NanoTest™ Xtreme™ is to prevent sample oxidation. This is essential when characterising near-surface properties, such as the effects of ion irradiation, surface treatments such as nitriding, or properties of CVD and PVD coatings at elevated temperatures.

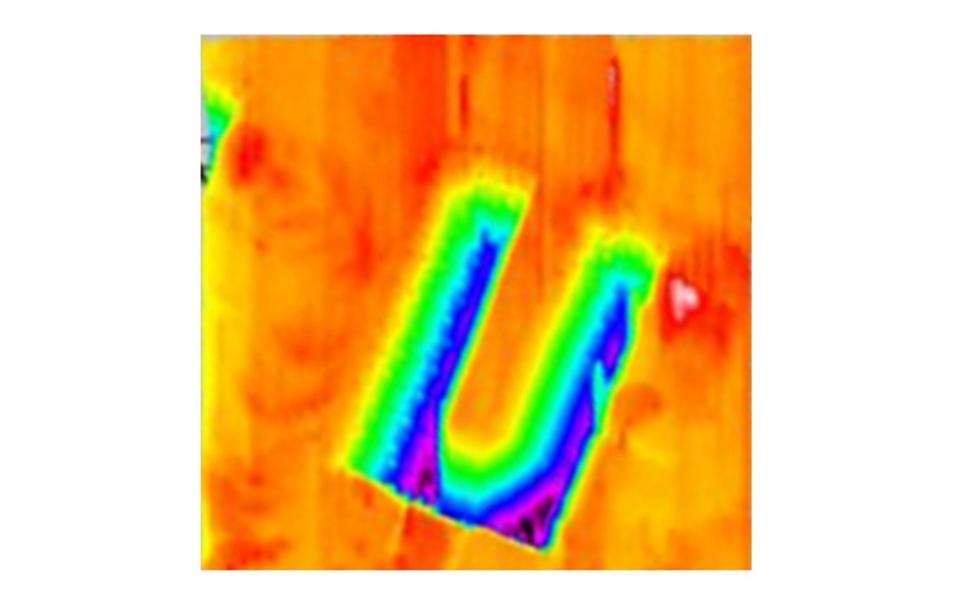

A micro-cantilever FIB machined into the surface of a Si wafer. The cantilever has been imaged using the indenter as the imaging probe and then a bend test performed after selecting contact point from the image. Image and tests were performed at 700 °C under high vacuum.

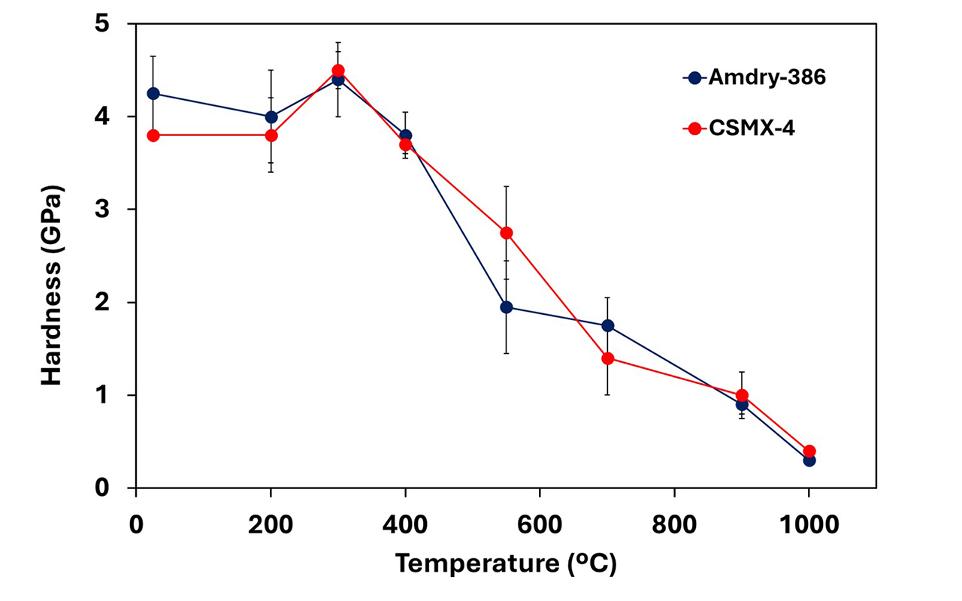

Temperature dependence of a nickel-based amdry bond coating between room temperature and 1000 °C.

As diamond and cubic boron nitride both react with the nickel alloy at high temperatures, this work was performed with a sapphire indenter.

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.