Humidity Testing Solutions for Material Properties

Humidity

Technical Notes

Precision Humidity Control for Nanomechanical Testing

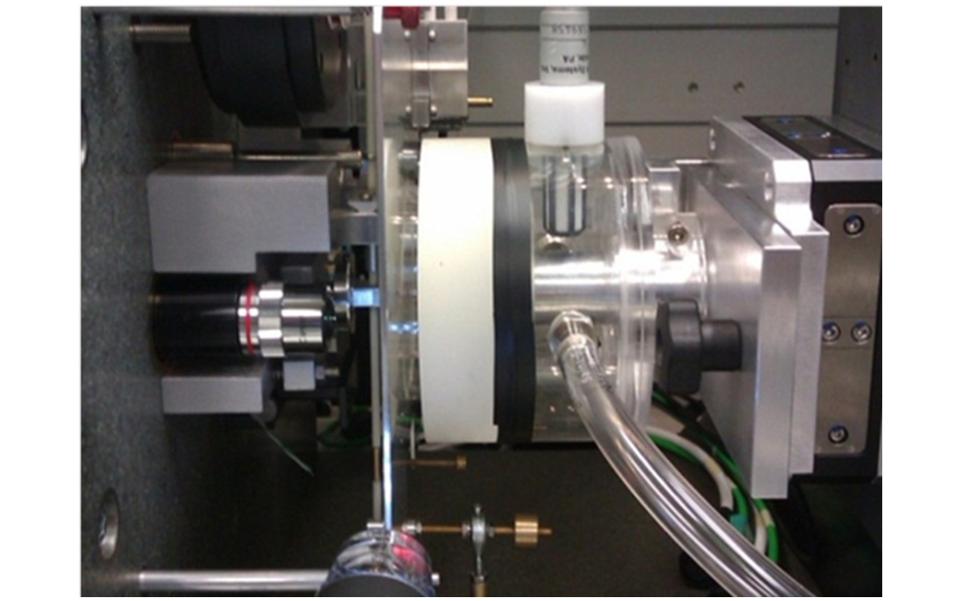

The humidity cell allows samples to be tested in environments of between 10 and 95% RH.

The test cell volume is sufficiently small to attain the target set point quickly but large enough to test samples up to several cm square in size. It is possible to heat samples up to 90 °C.

All test types including indentation, scratch and wear and impact tests are possible in the humidity cell.

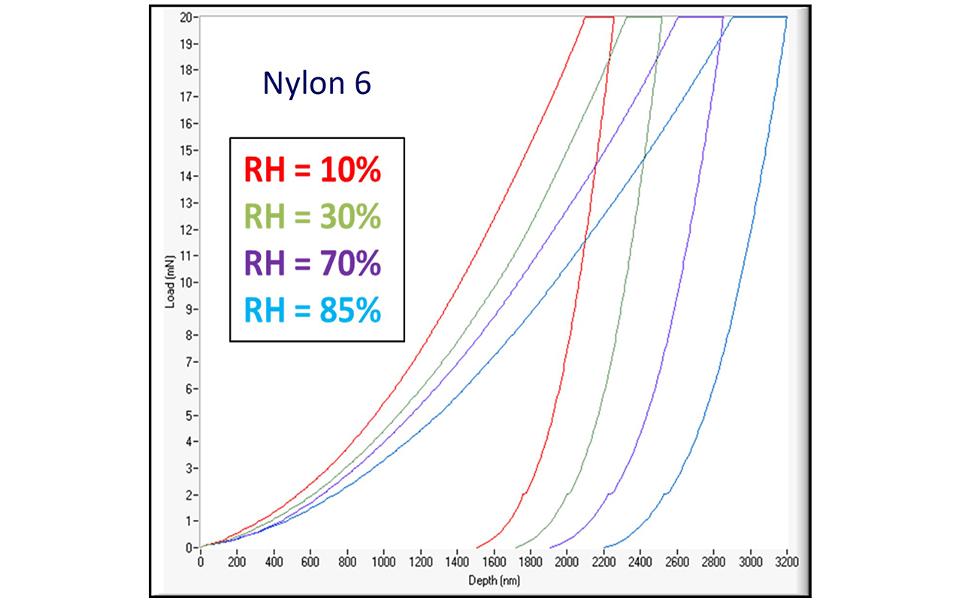

Mechanical properties of very hygroscopic materials such as Nylon 6 can be strongly humidity dependent.

In this case clear differences are seen in terms of stiffness (from the initial part of the unload curve), and time-dependent deformation during the maximum load dwell period.

The humidity control system allows quick and precise control of relative humidity levels from 10% to 95%. The test cell is big enough to allow testing of samples over 50 mm x 50 mm without any need to cut.

All test techniques; nanoindentation, scratch/wear and impact, may be performed in the humidity cell.

A temperature-controlled humidity cell is available.

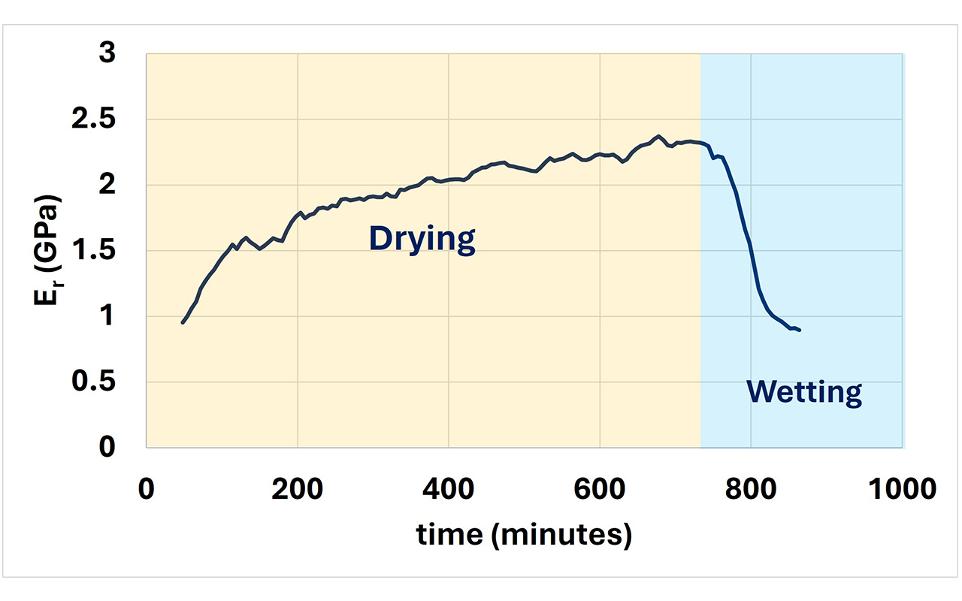

As the volume of the test cell is small and stabilisation at the target humidity is fast, it is possible to study how material properties change as wetting and drying is occurring.

Response to drying is slow, response to wetting is very fast.

Humidity may be altered whilst experiments are running, in this case it was changed from 85% to 30% then back to 85% whilst nanoindentation experiments were running.

The humidity cell may be used to preserve the condition of samples during testing, this is essential for materials such as bone as their properties change very significantly as they dry.

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.