Intellectual Property of Micro Materials: Innovations in Nano Testing

Our Patented Technologies in Nano Testing

HEATING IN MATERIAL TESTING APPARATUS

High temperature – Control of relative sample and tip temperature during indentation (Power lock method)

Publication Number : WO/2011/104529

Publication Date : 01.09.2011

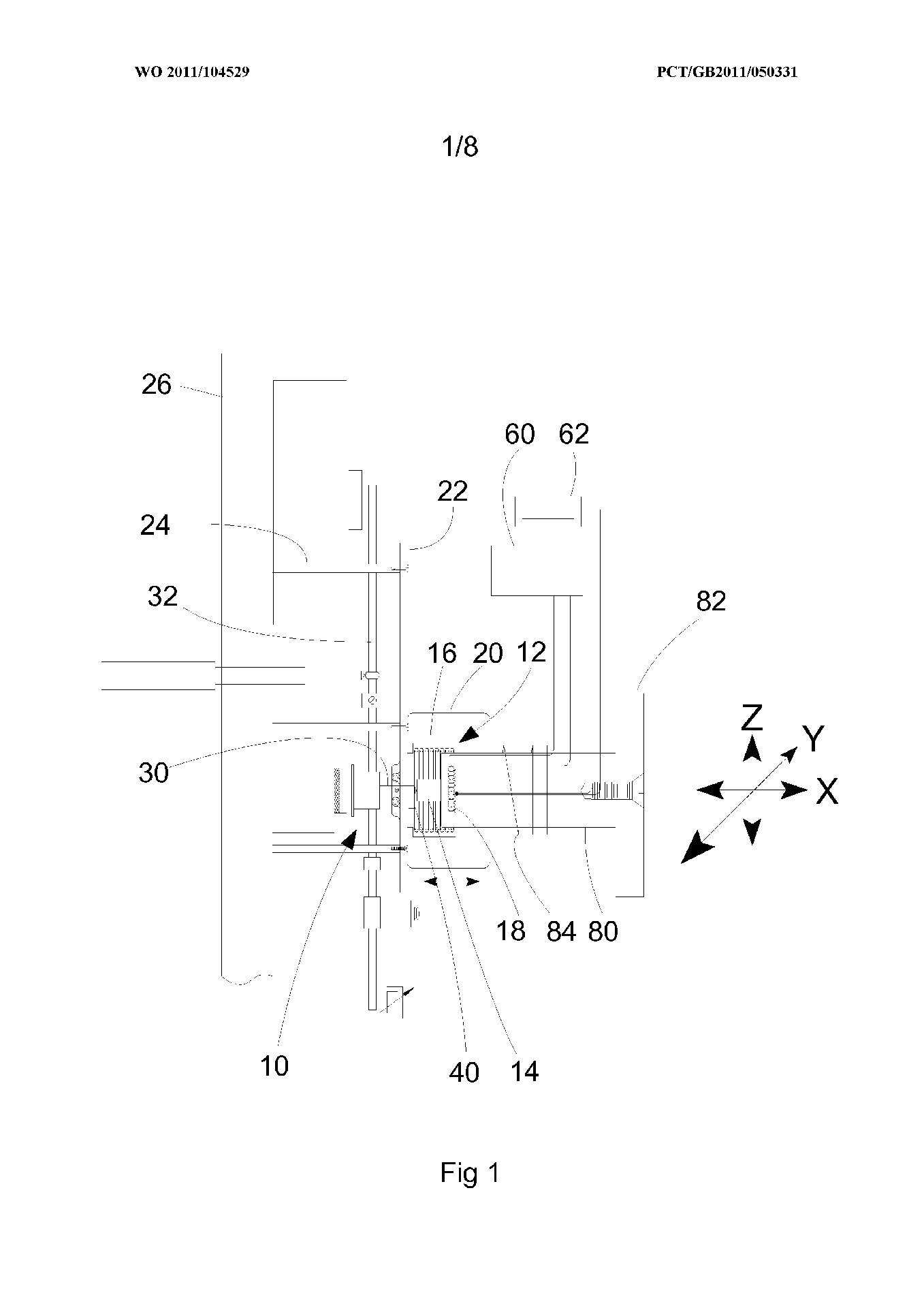

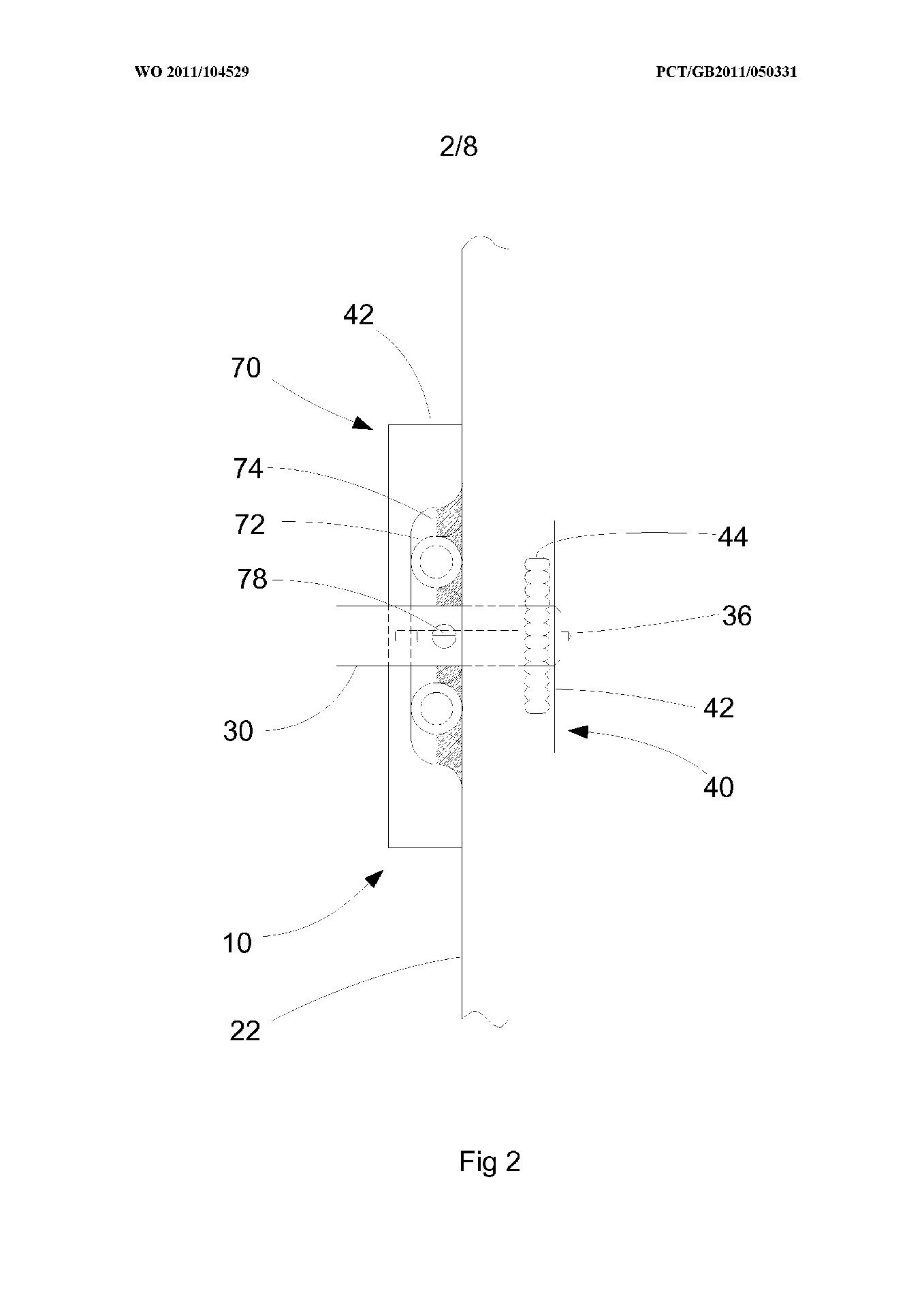

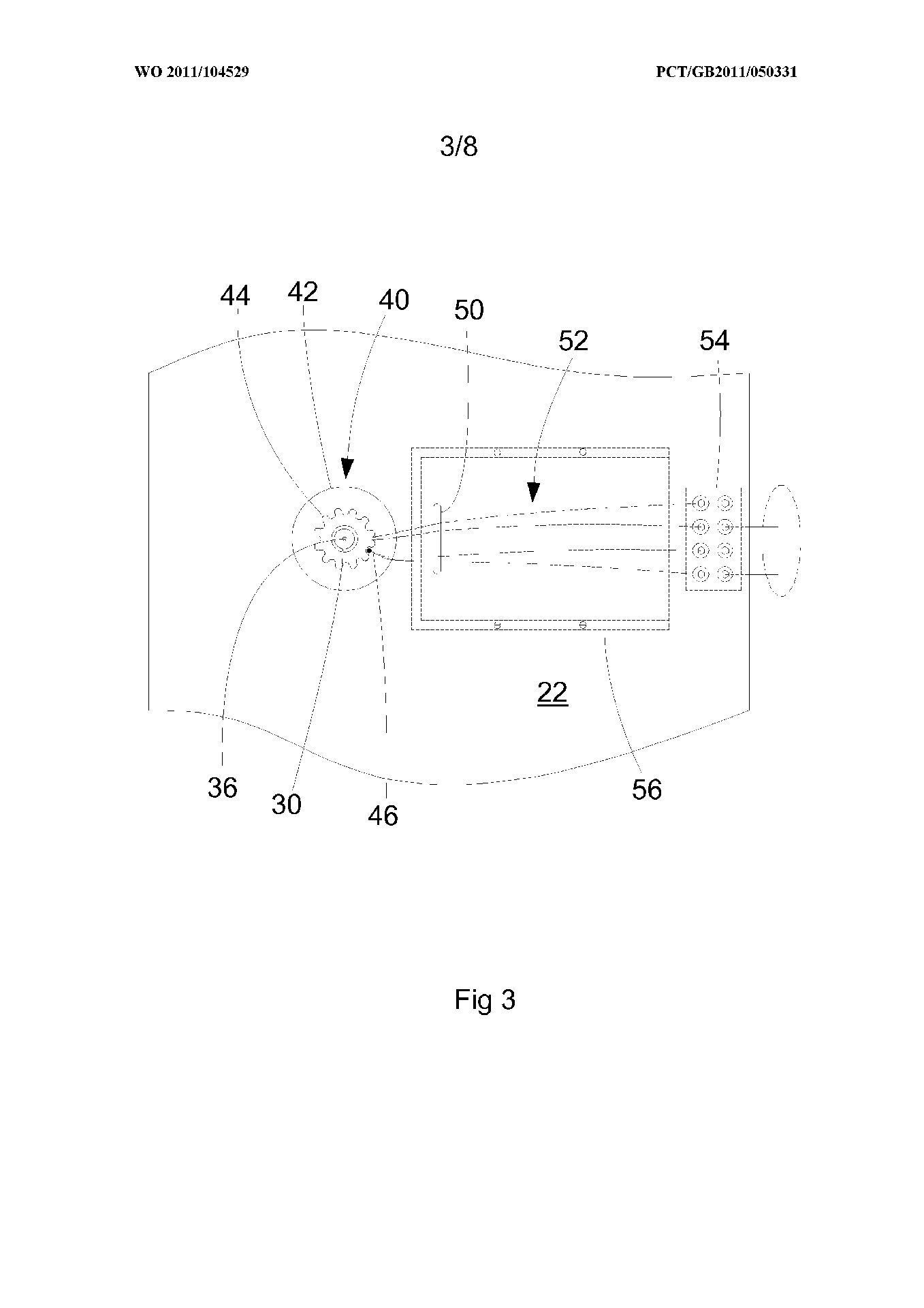

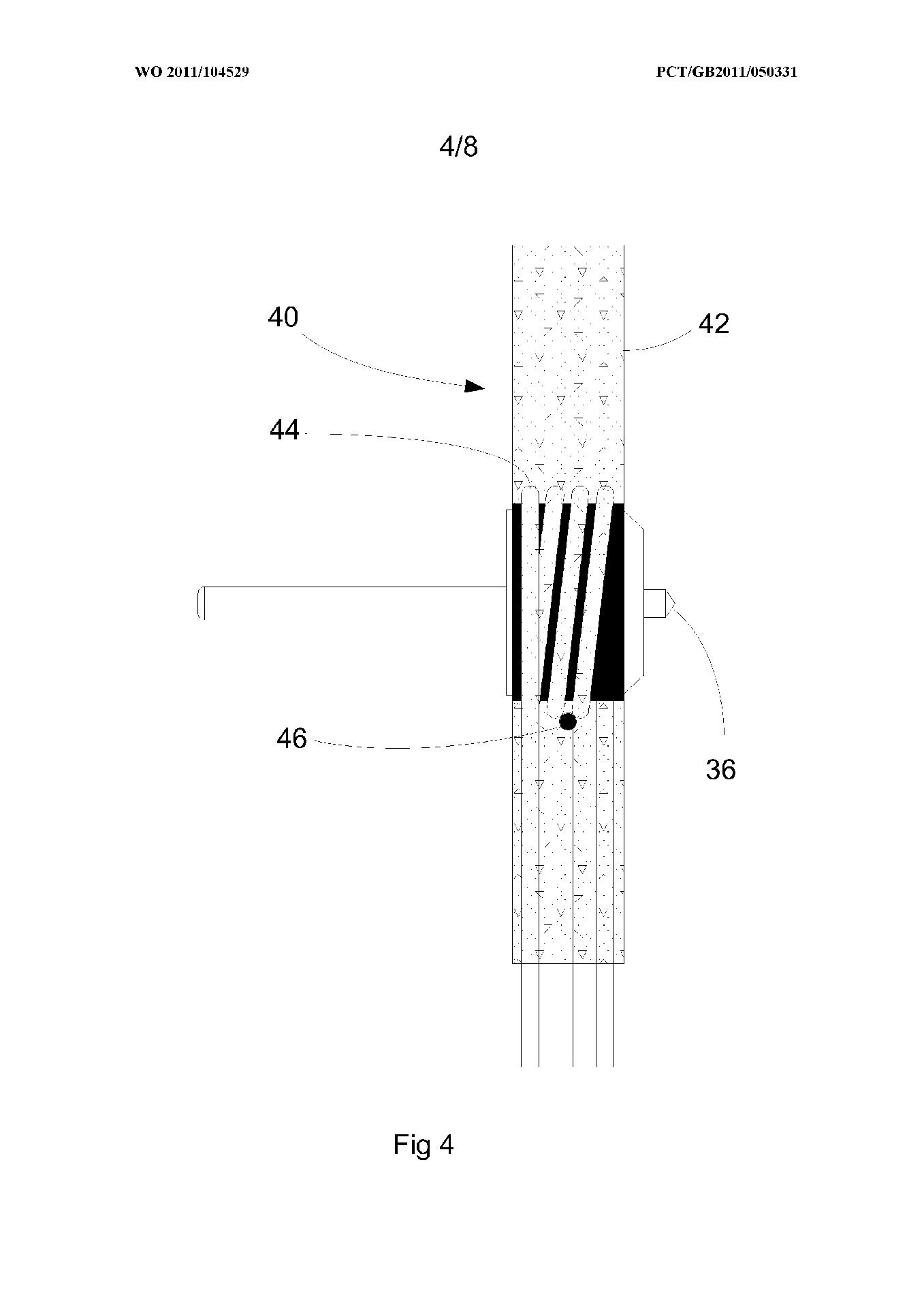

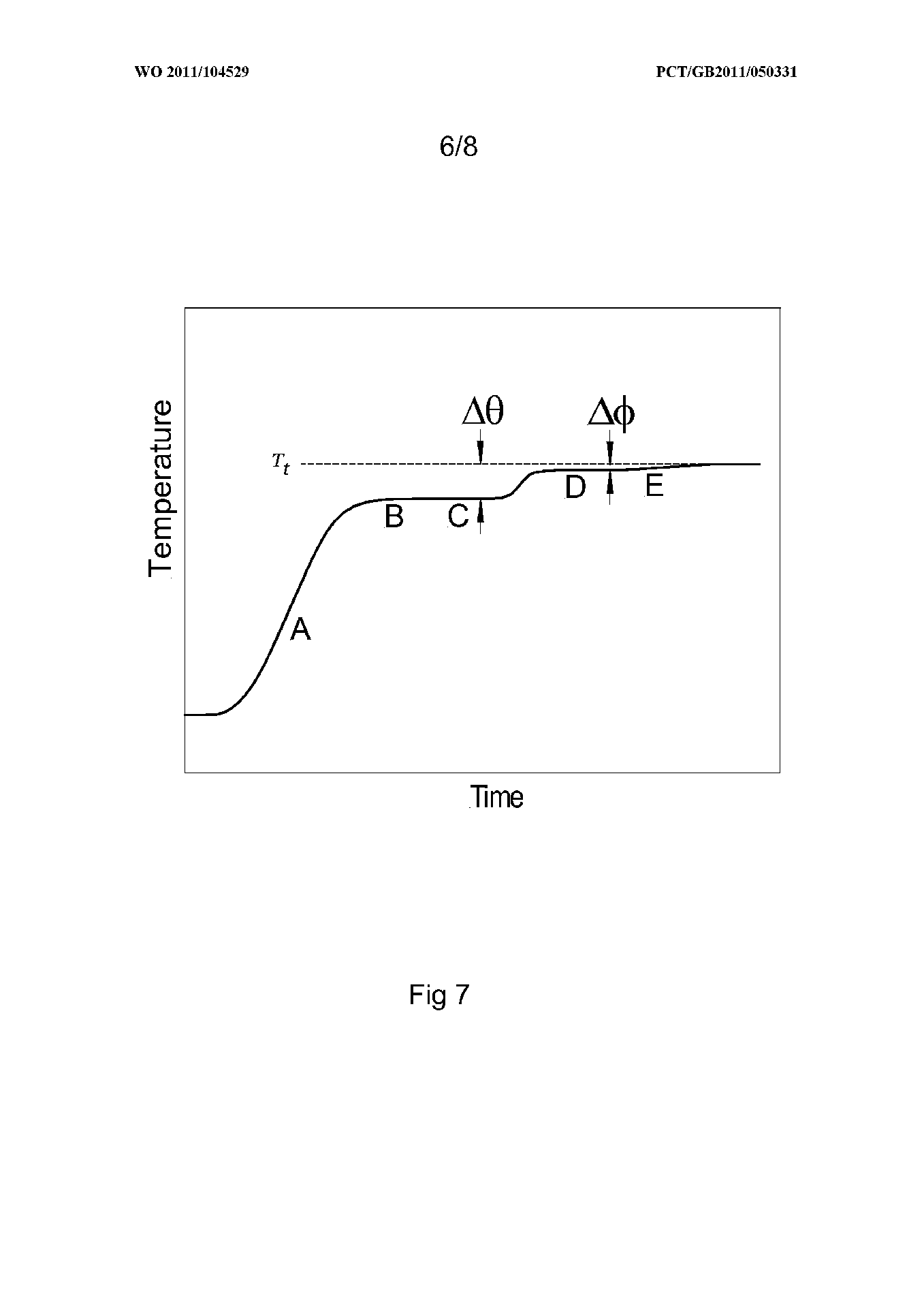

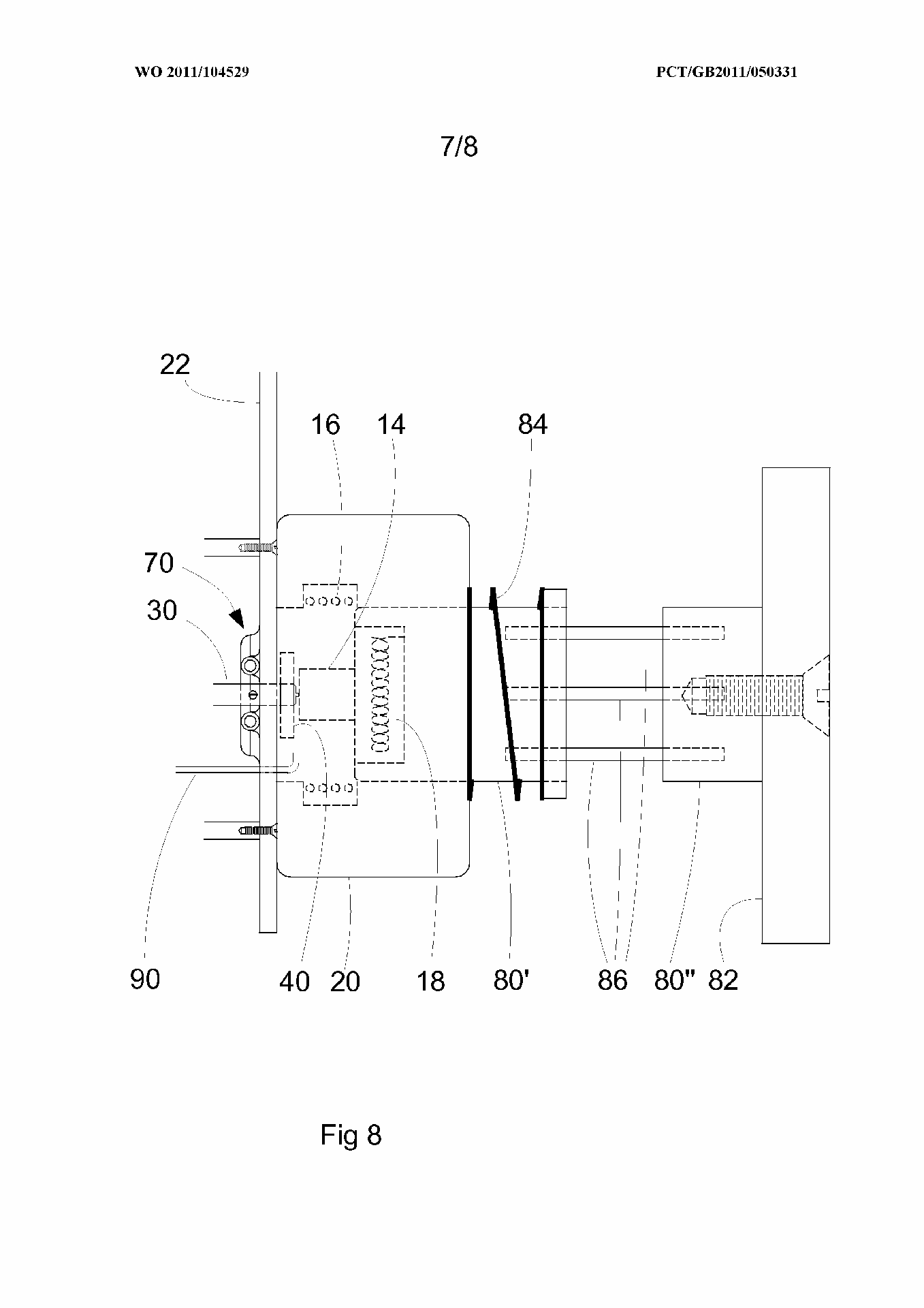

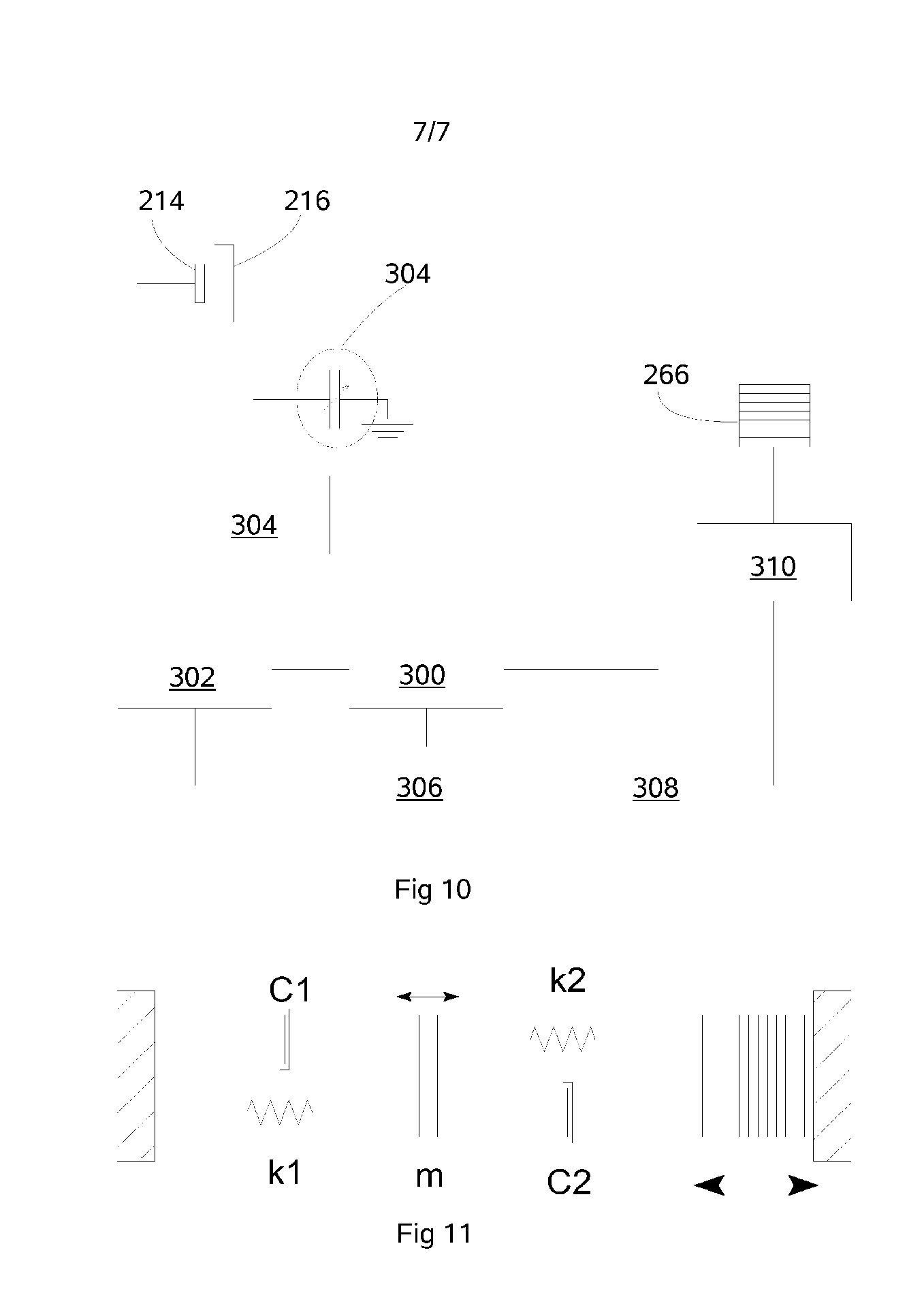

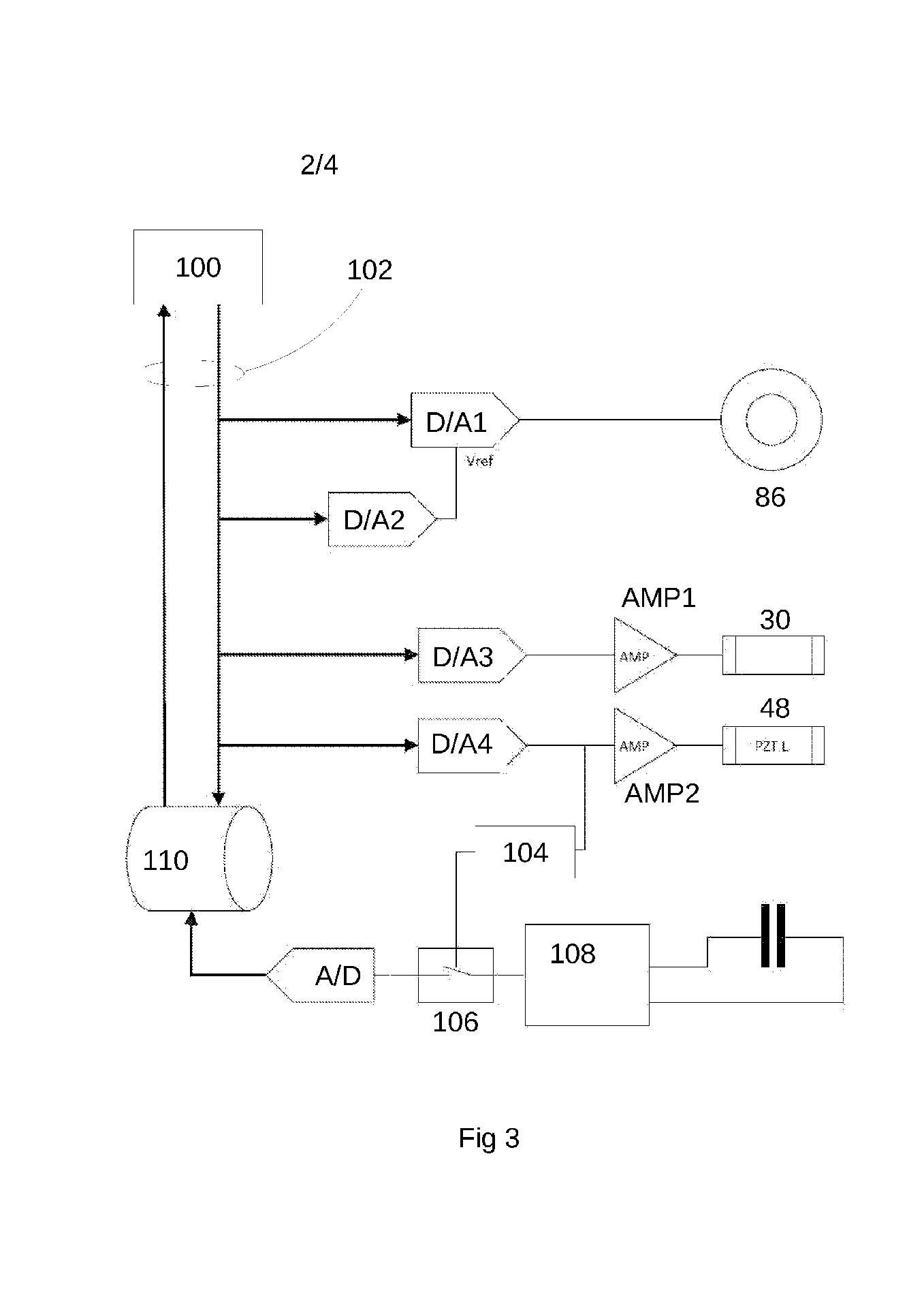

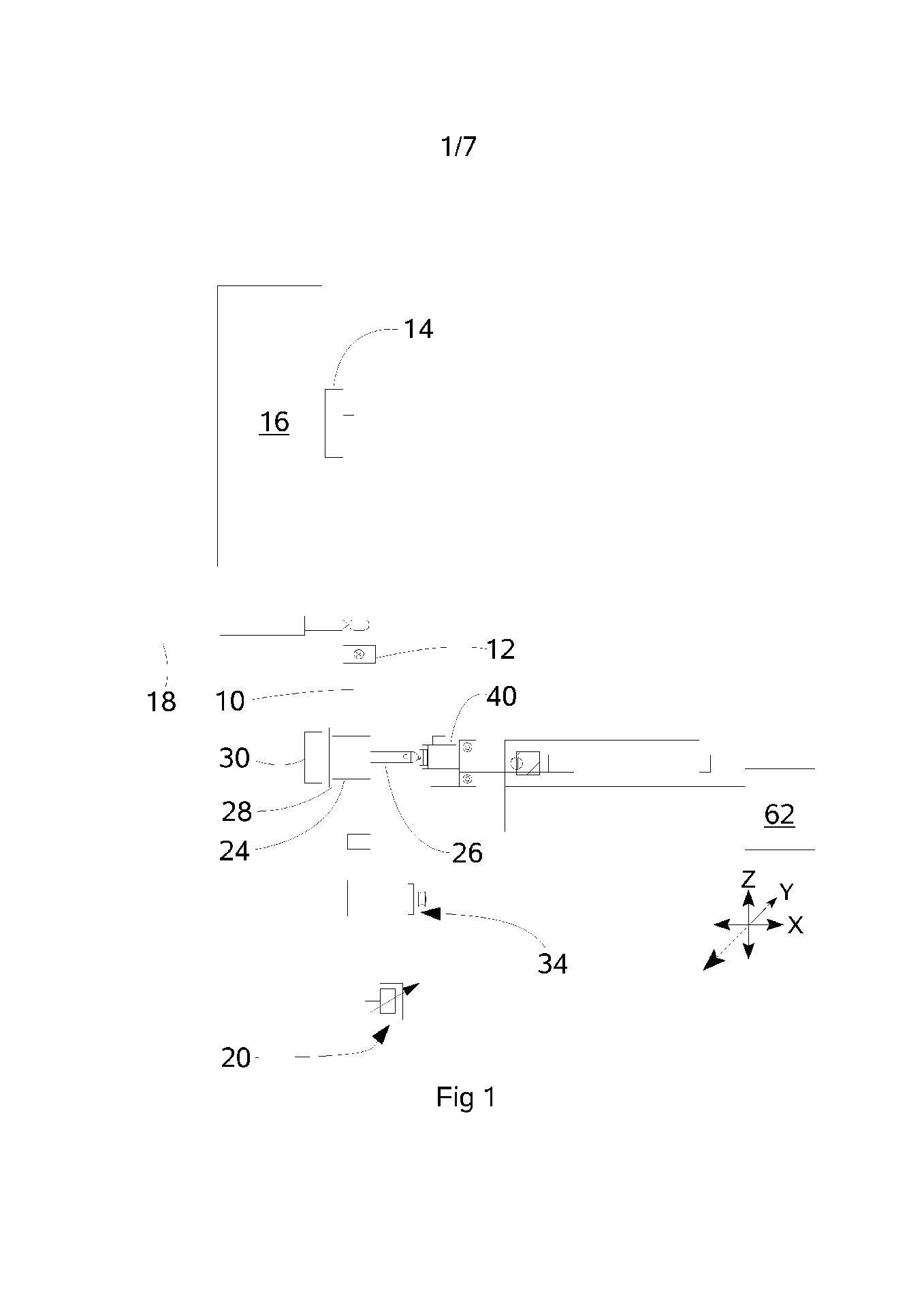

A method of controlling the temperature of a probe in materials testing apparatus, and apparatus operating by that method are disclosed. The apparatus includes heating elements that can by supplied with energy to apply heat to the probe. The method has a heating phase. In the heating phase, closed-loop temperature control is used to supply energy to the heating elements to heat the probe to a target temperature. When the probe has reached the target temperature, the average power that is being supplied to the heating elements is determined. Then, in a temperature maintenance phase, a continuous constant source of energy at a power that is substantially equal to the determined average power is supplied to the heating elements to maintain the probe at the target temperature.

|

|

|

|

|

|

|

|

Ref: World Intellectual Property Organization (WIPO)

Apparatus and method for testing materials

Testing surface frictional properties of materials on a scale down to that of nanometres. A method and apparatus for measuring the frictional properties of a surface on a small scale by direct measurement of the energy dissipated at a sliding probe-sample contact. The measurement of frictional force is not required.

Application Number : GB1113240.4

Publication Date : 08 February 2012

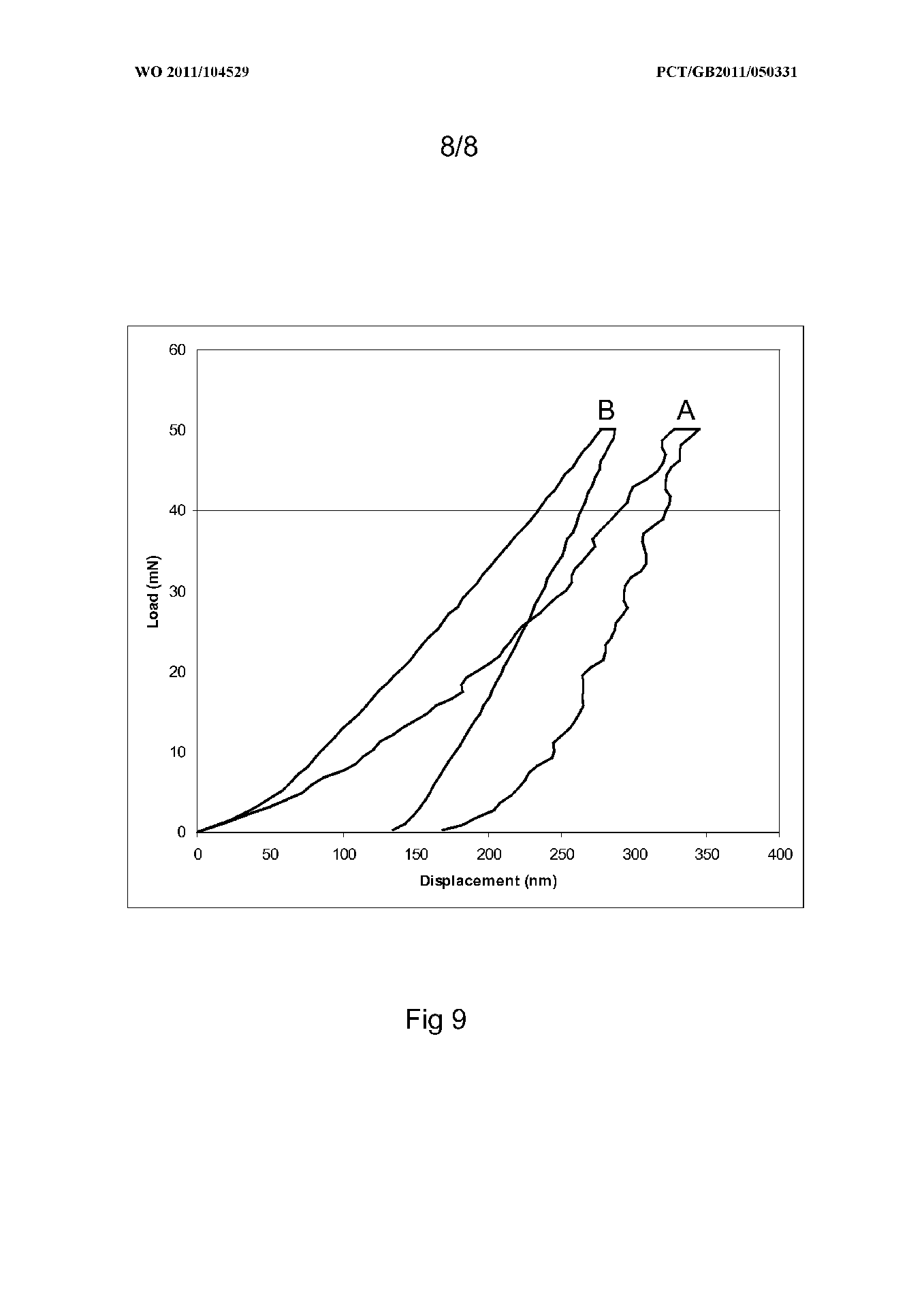

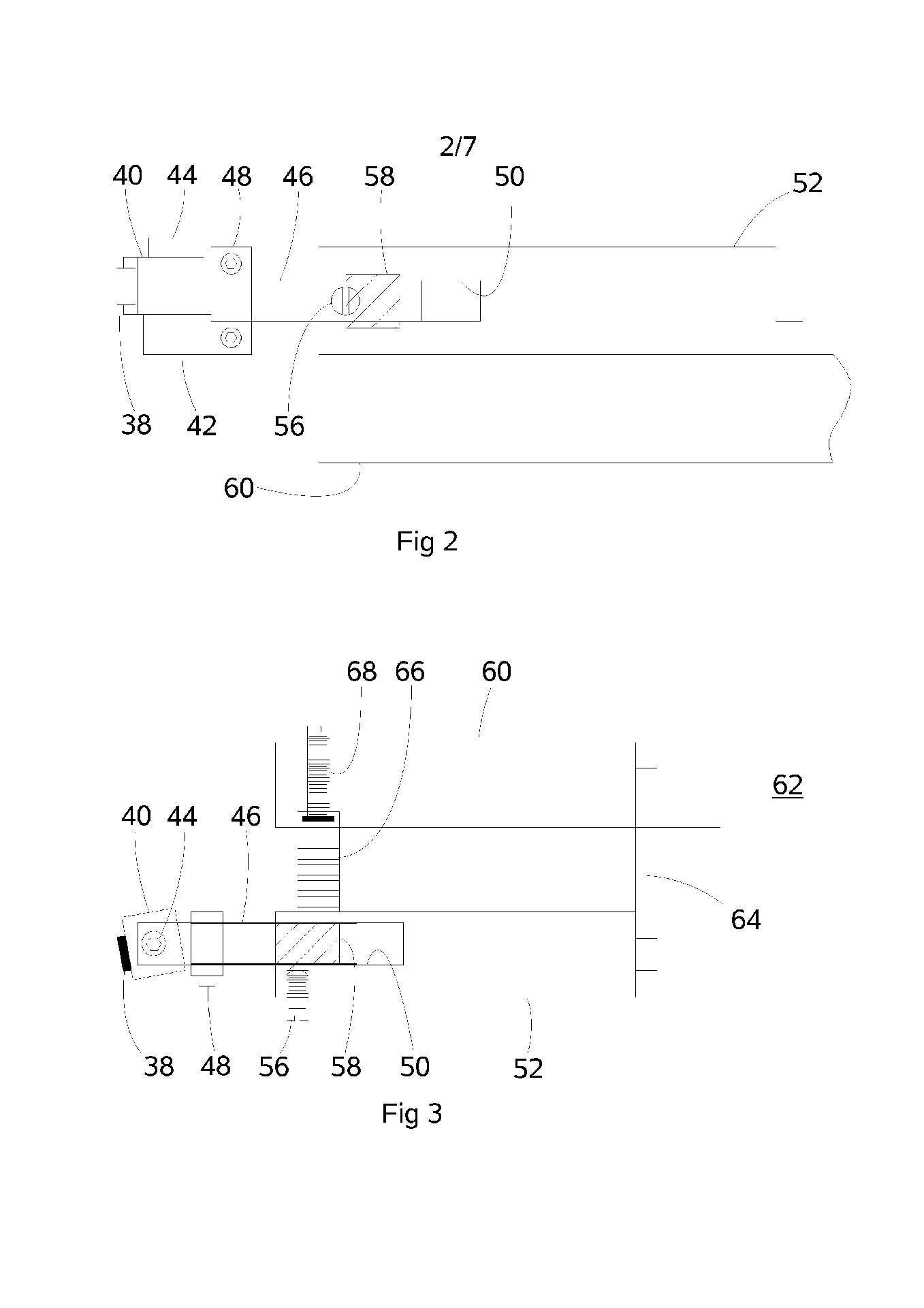

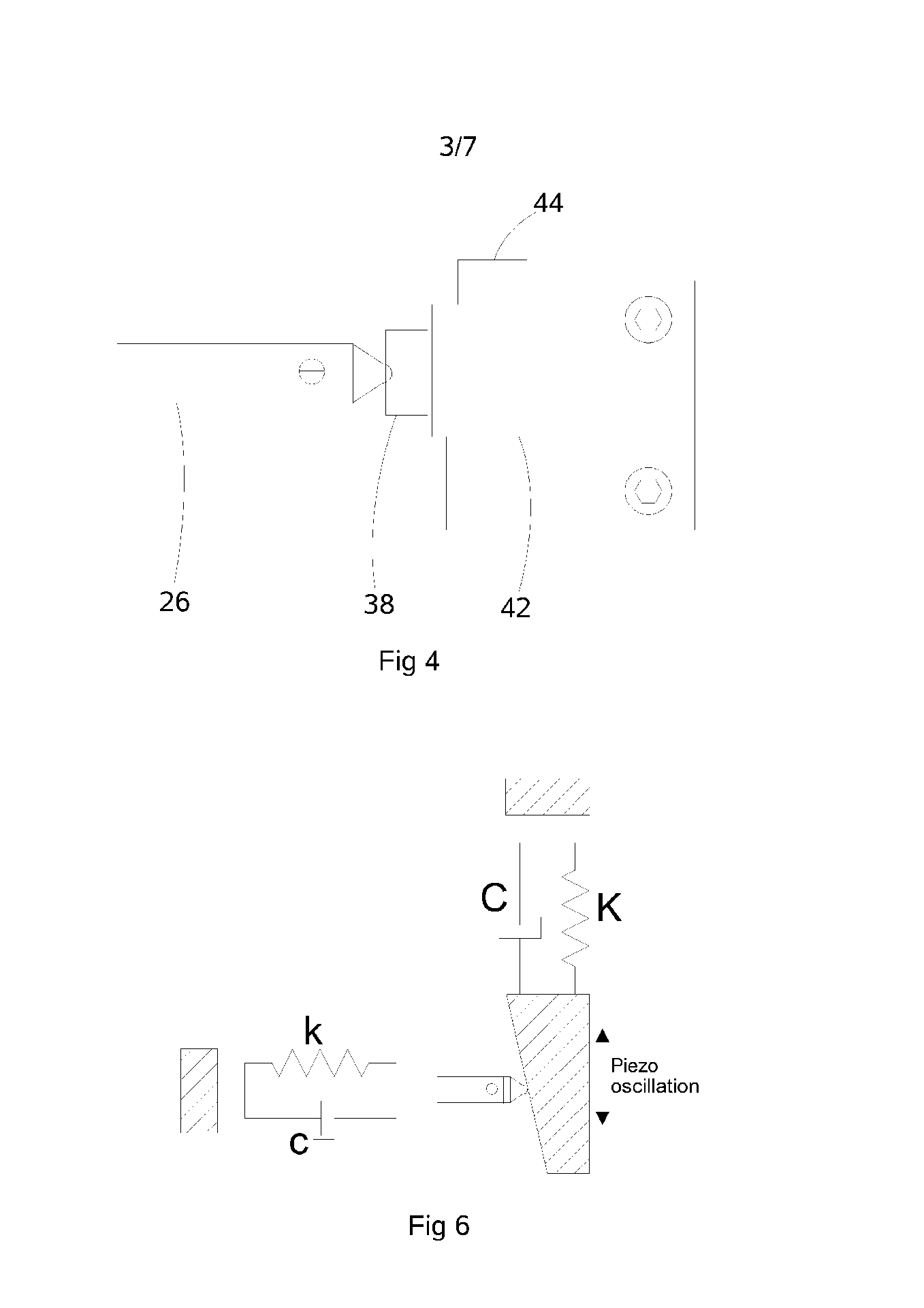

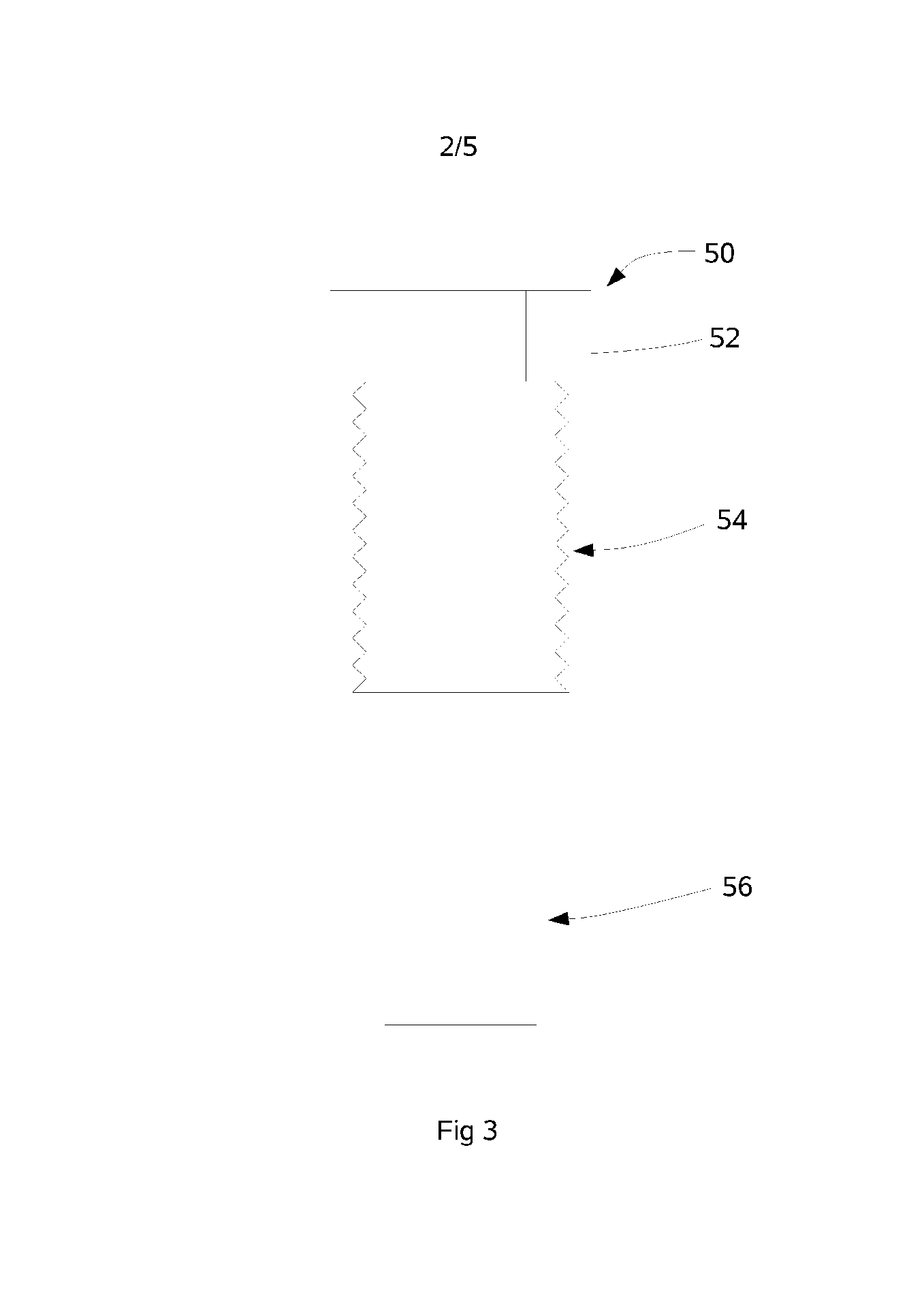

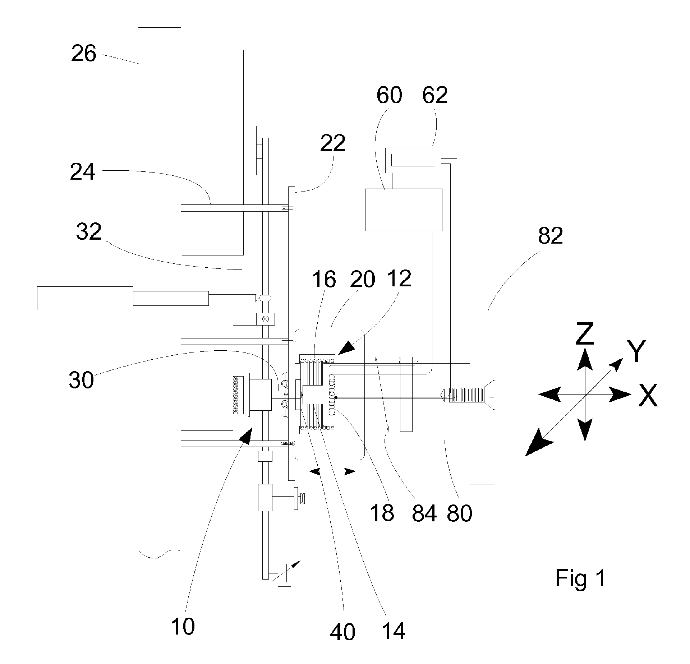

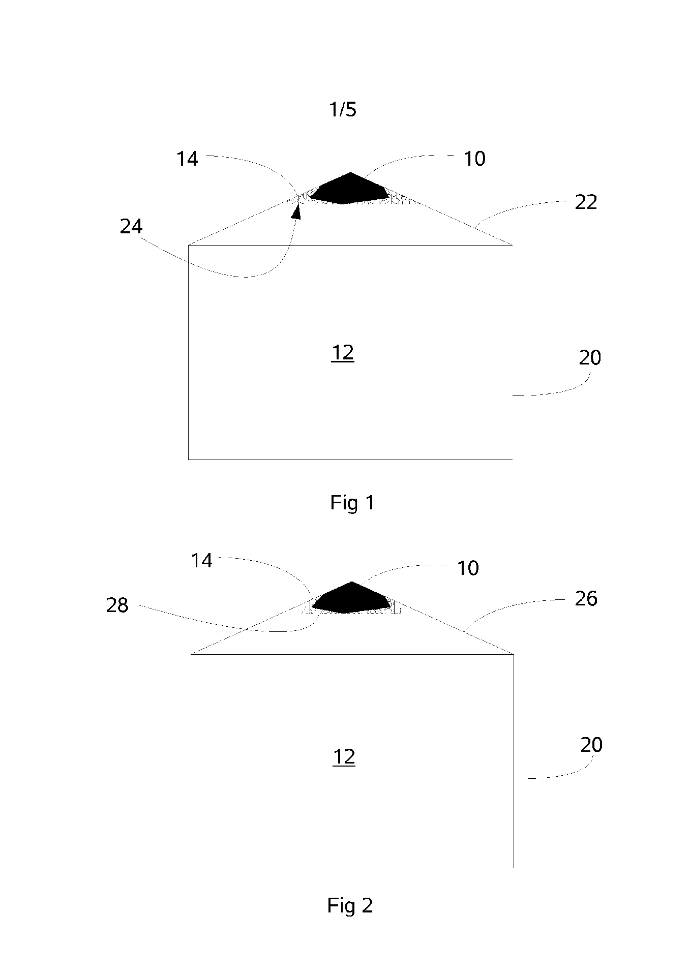

Apparatus and a method for testing surface properties of a sample are disclosed. The apparatus comprises a sample holder 40 and a probe 26, with the apparatus operative, with a sample held in the sample holder to oscillate the sample holder with the probe in contact with the sample to cause the probe to oscillate, to measure the phase difference between the oscillations of the sample holder and the probe and the amplitude of the probe, and to determine the contact damping coefficient between the probe and the sample, and thereby calculate the instantaneous power transmitted between the sample and the probe. Alternatively, the probe may be oscillated and resultant oscillation of the contacting sample may be measured to determine the damping coefficient.

|

|

|

|

|

|

GB2482595 - Apparatus and method for testing materials

Ref: Ipsum - Online Patent Information and Document Inspection Service

Test probe for materials testing apparatus

Mounting of test probe for use at elevated temperatures (>400°C)

Application Number : GB1115735.1

Publication Date : 13 March 2013

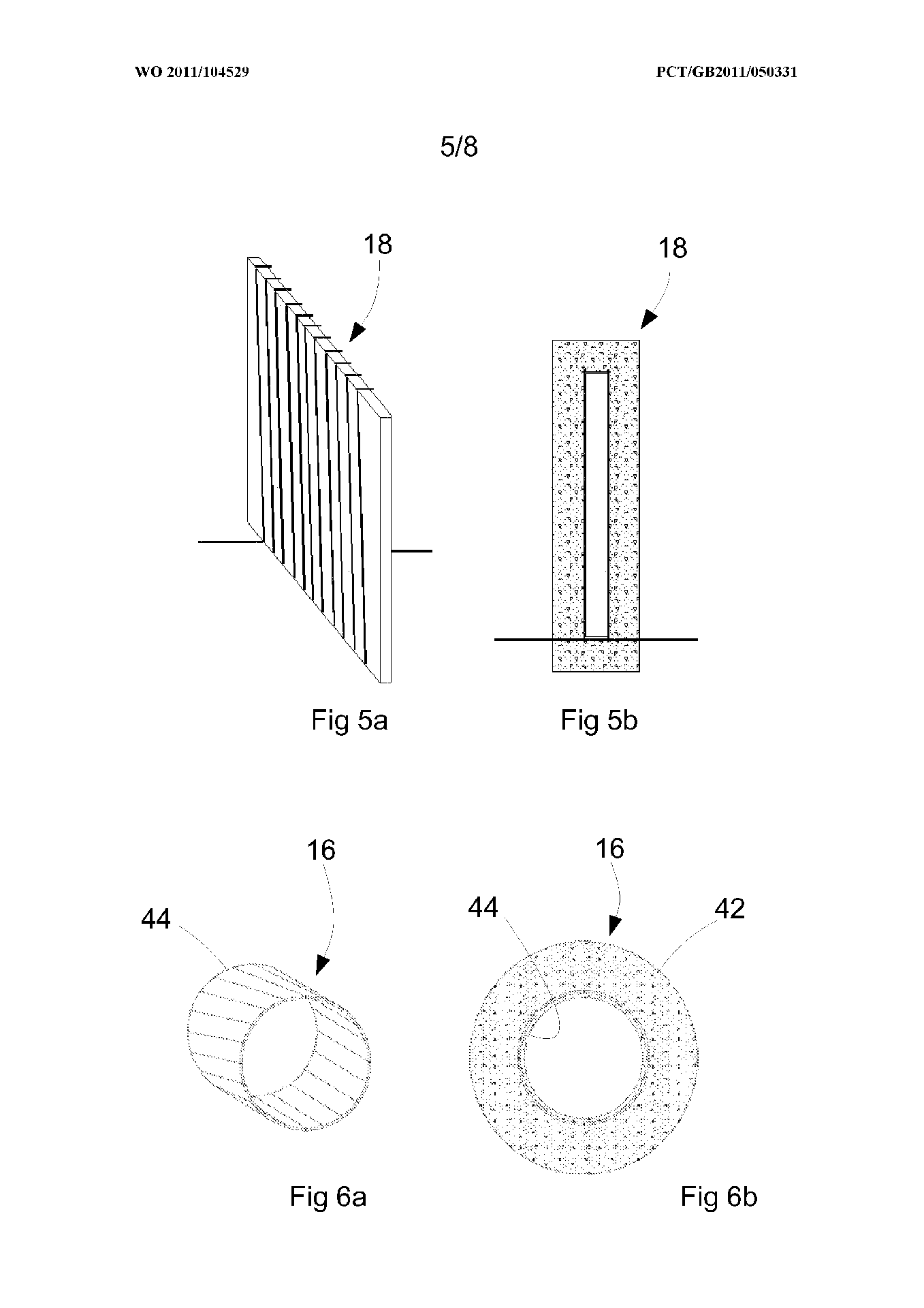

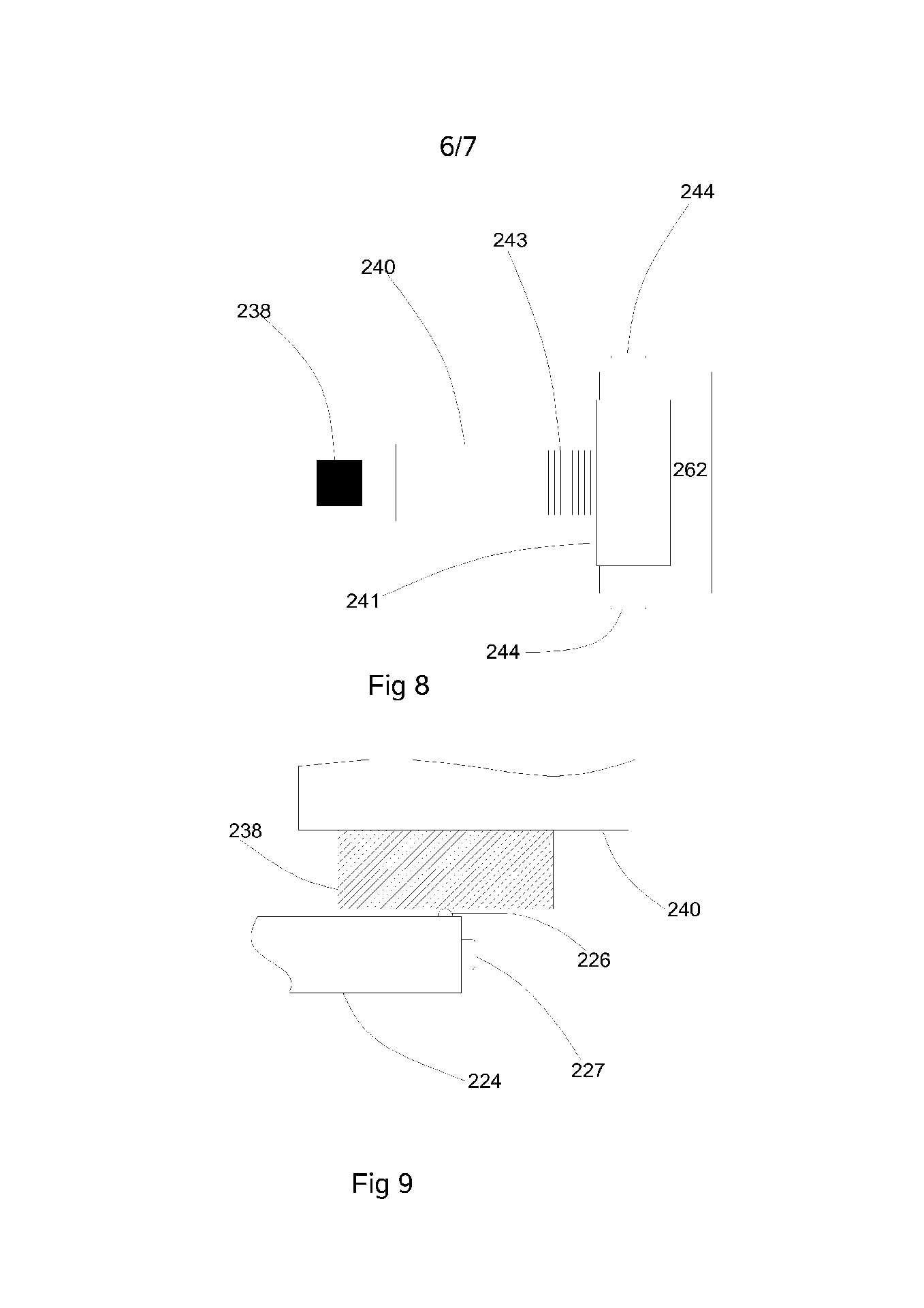

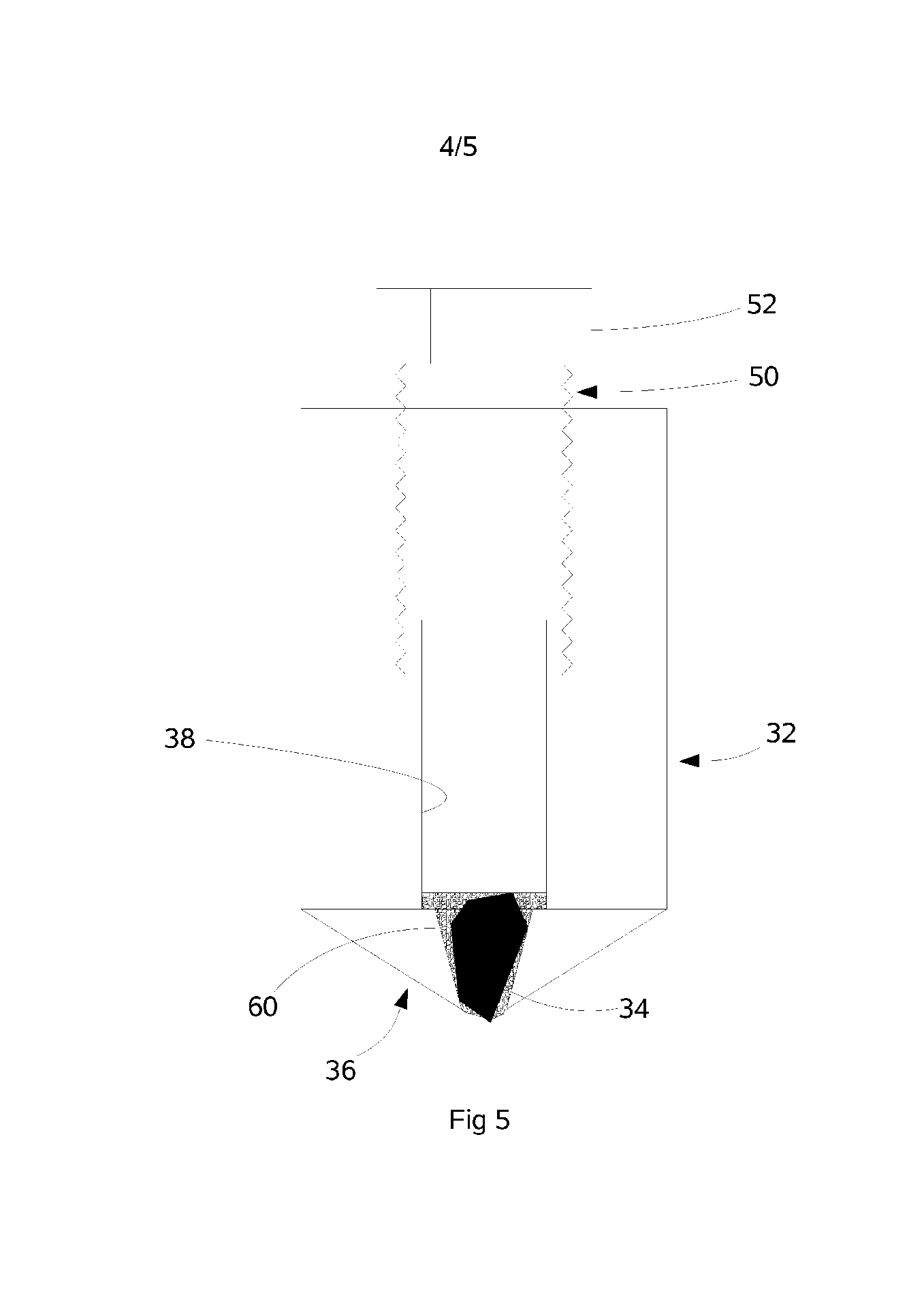

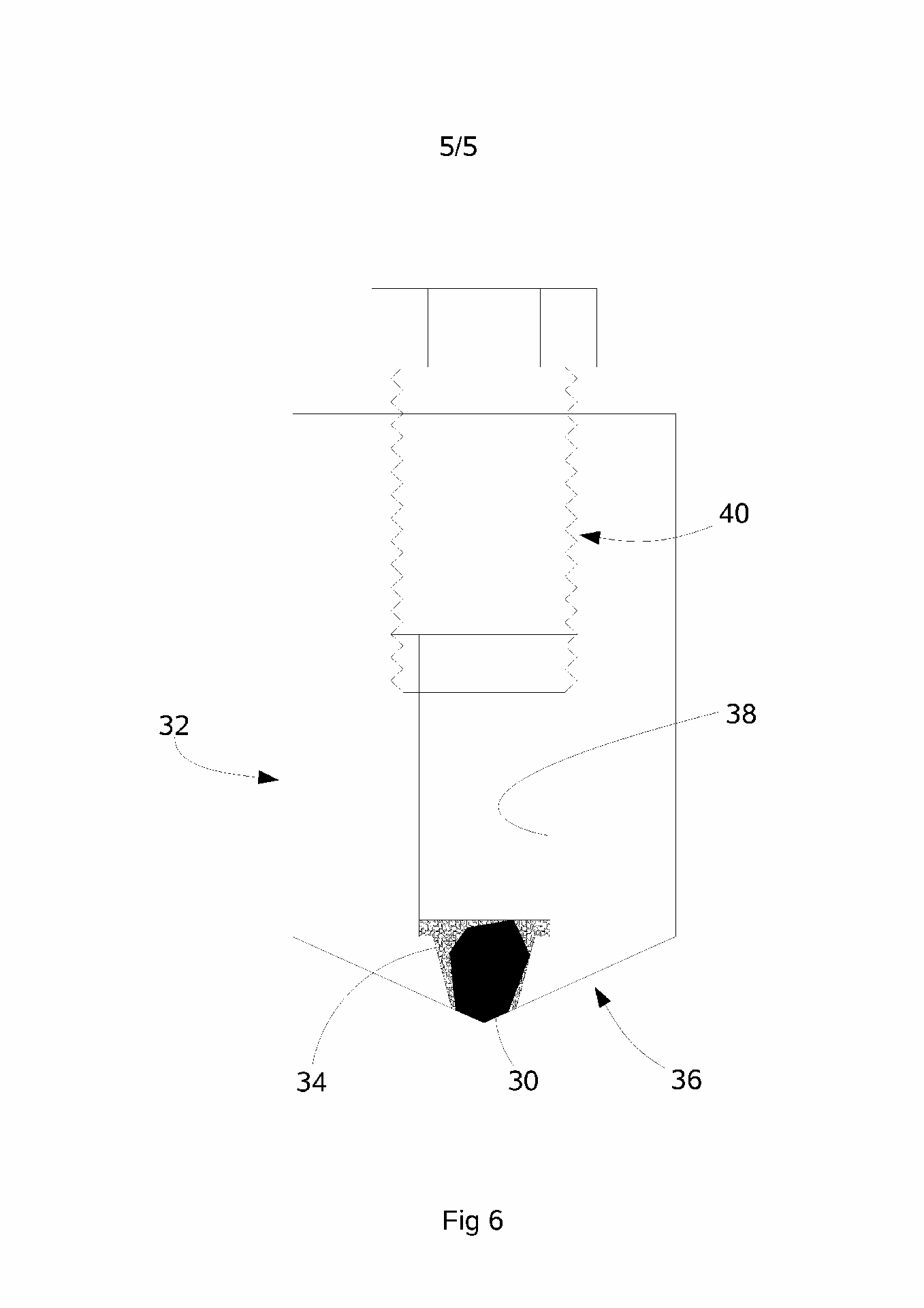

A test probe for use in materials testing apparatus is disclosed. The test probe comprises a probe holder adapted to be mounted for use on materials testing apparatus. A probe tip is carried on the probe holder. The probe tip is secured to the probe holder by a body of ceramic cement, such as cement formed of cured soluble silicate. The probe tip may be carried on a flat surface of the probe holder, within a recess of the probe holder, or in a space within the probe holder.

|

|

|

|

GB2494467 - Test probe for materials testing apparatus

Ref: Ipsum - Online Patent Information and Document Inspection Service

Surface testing equipment and method

Impact – method for measuring surface properties. Apparatus for small-scale impact testing in which high strain rates are produced in a localised small volume. This enables thin film properties to be measured with minimal influence from the underlying substrate.

Application Number : WO/2000/004368

Publication Date : 27.01.2000

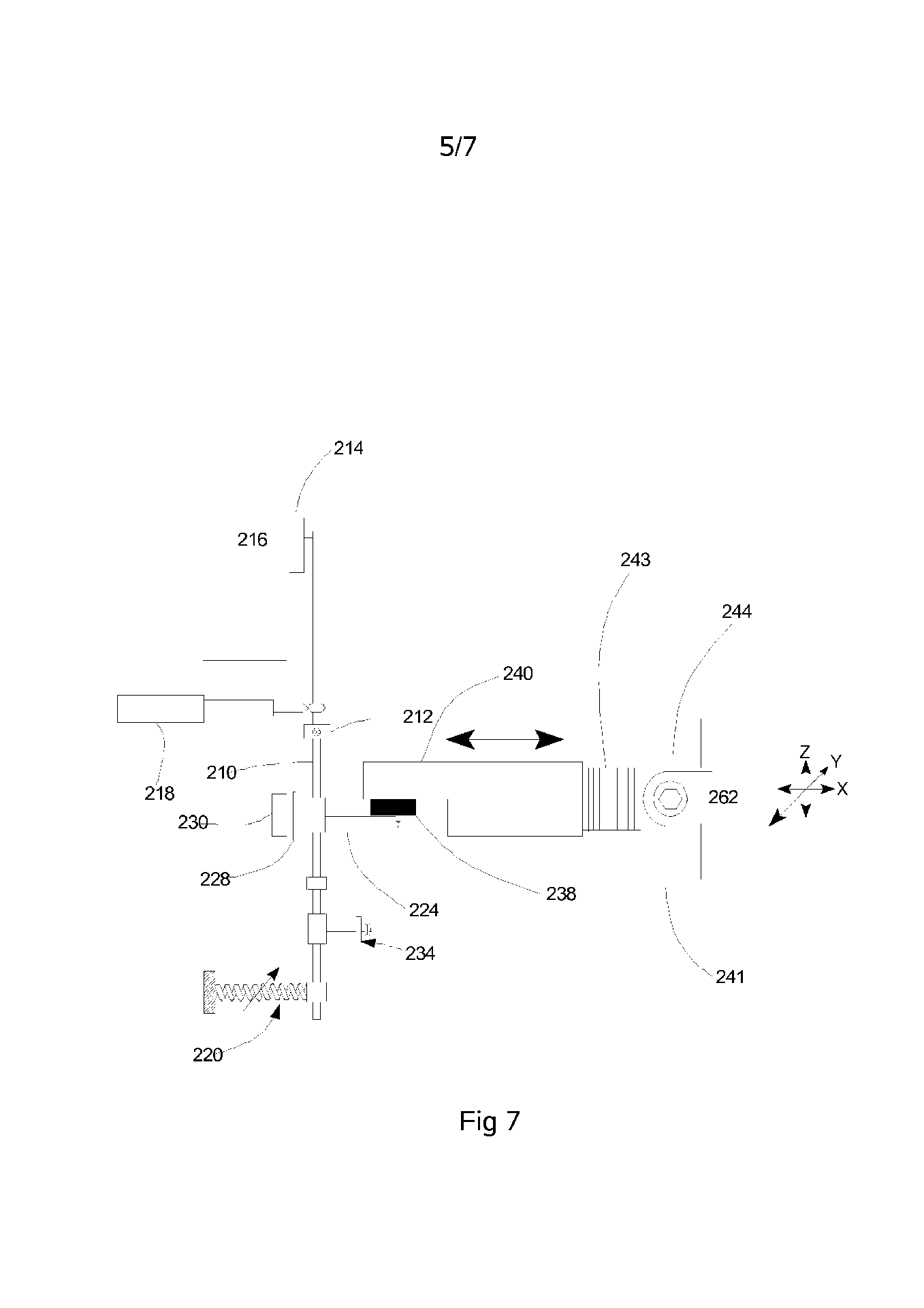

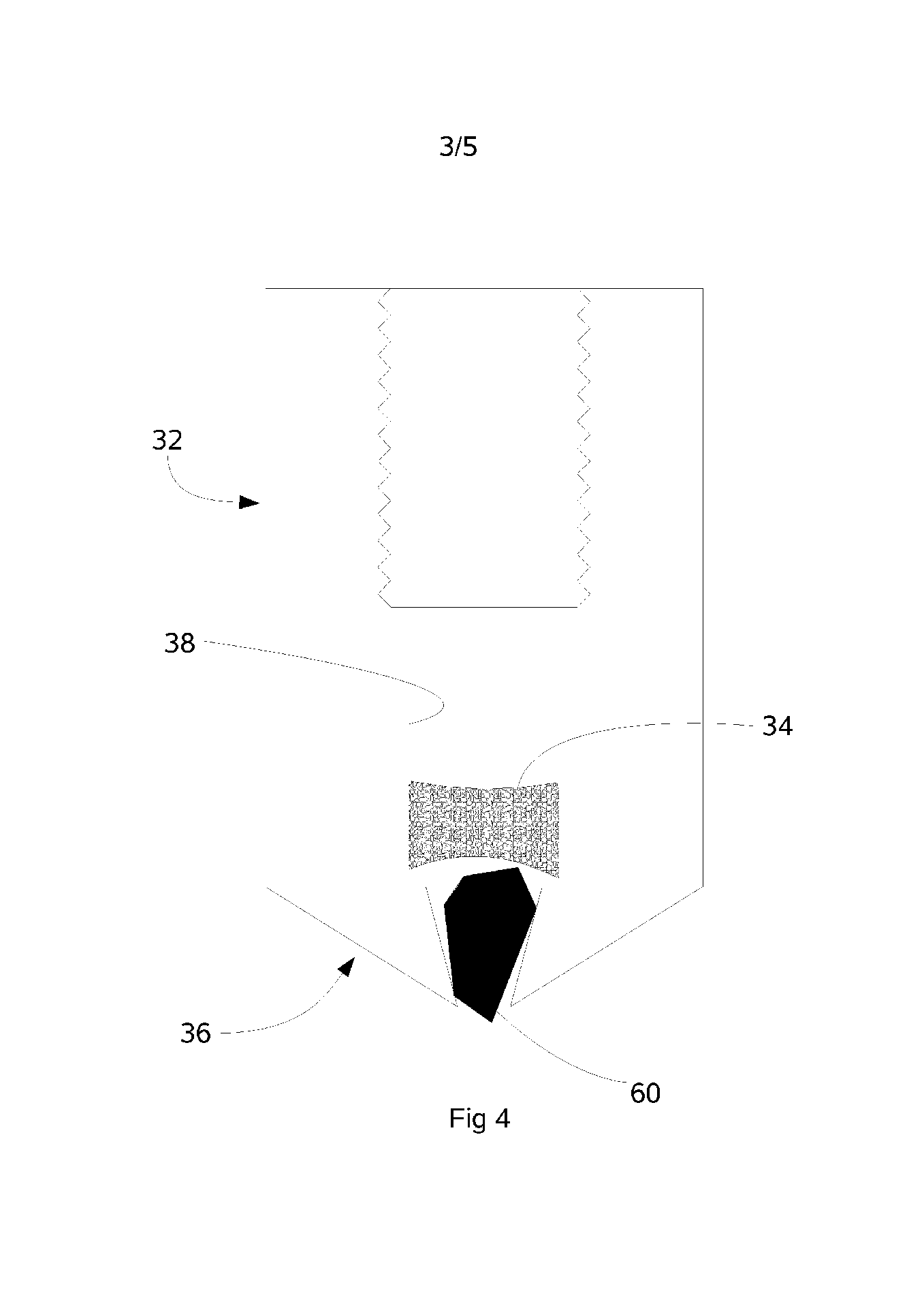

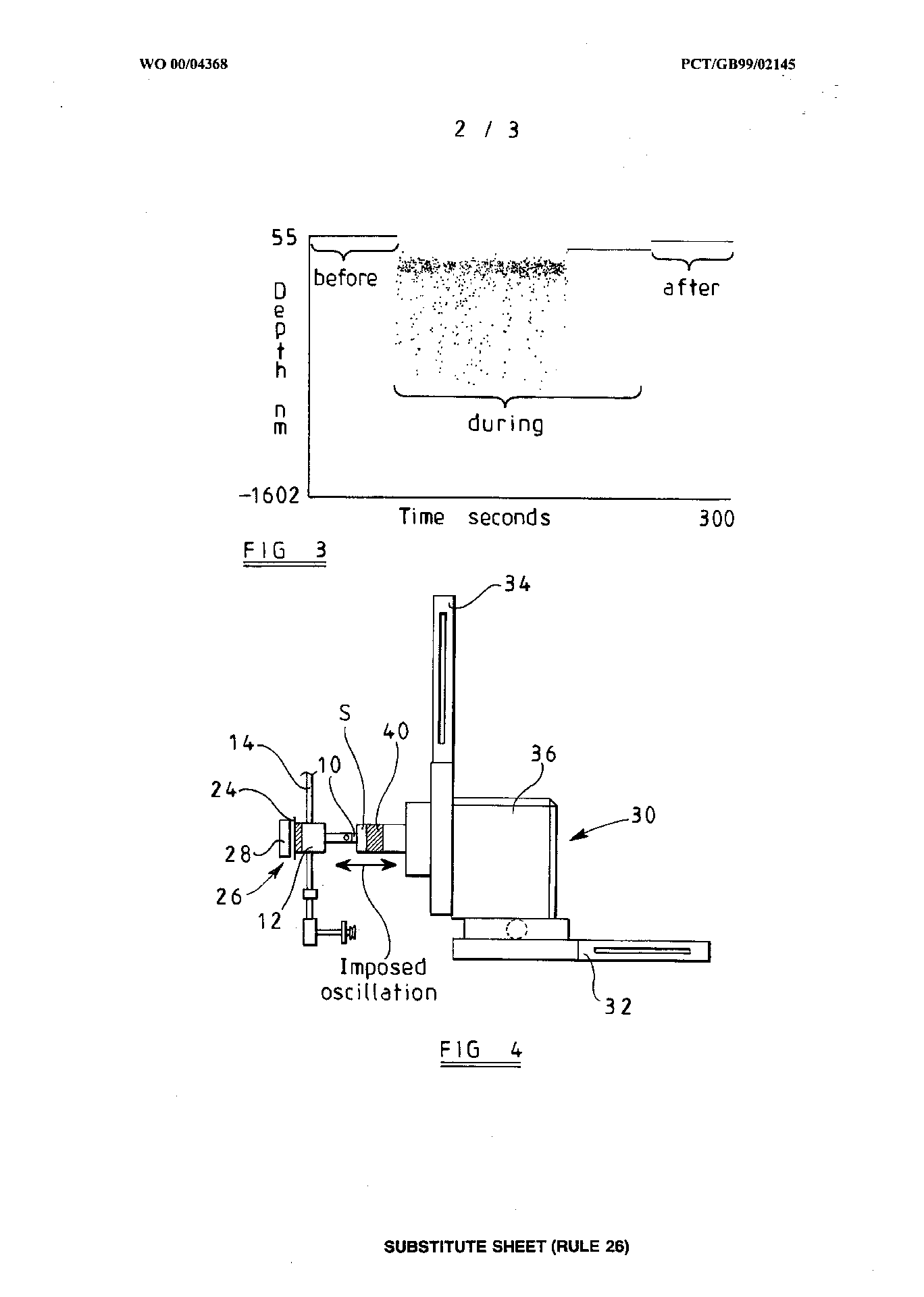

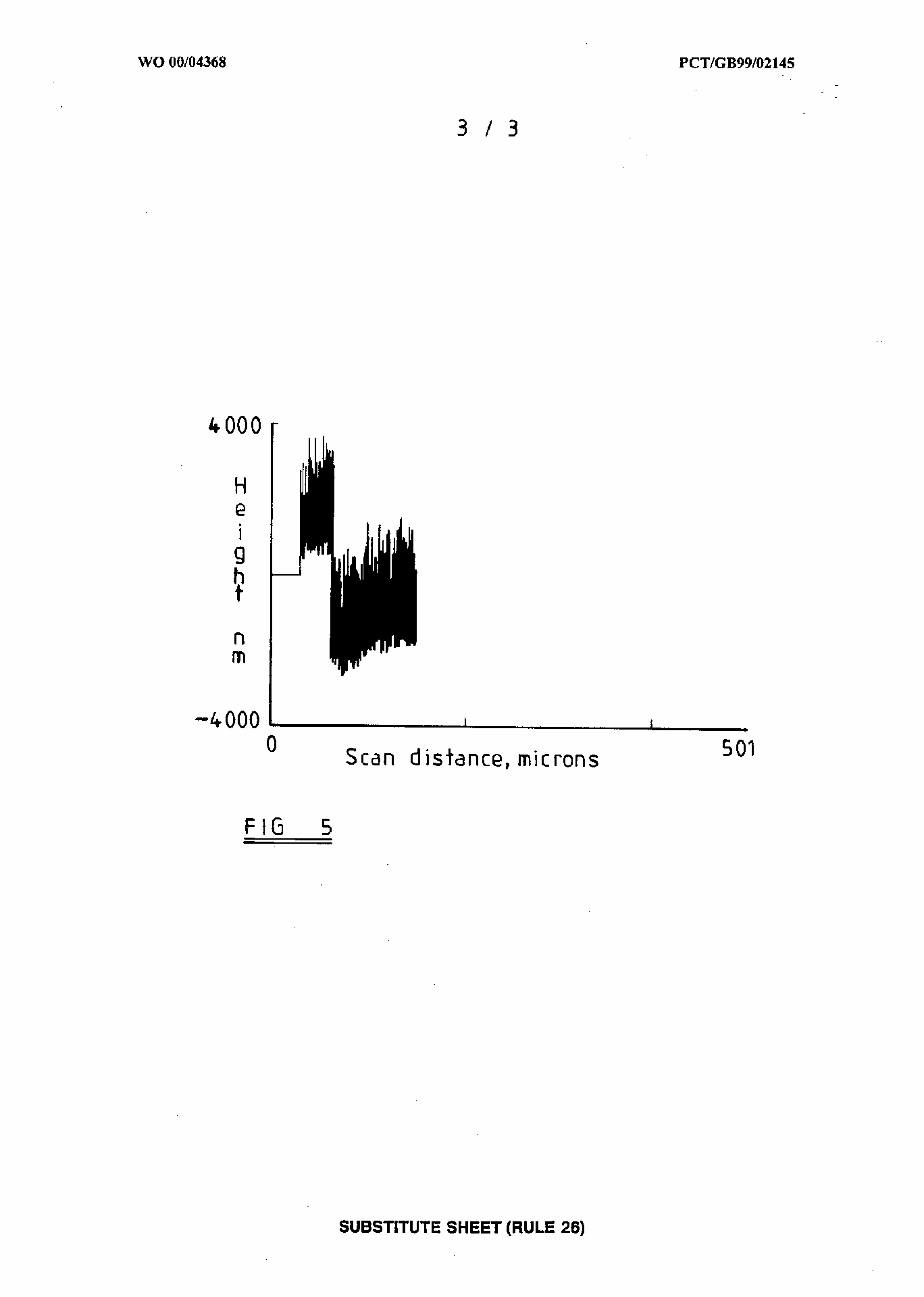

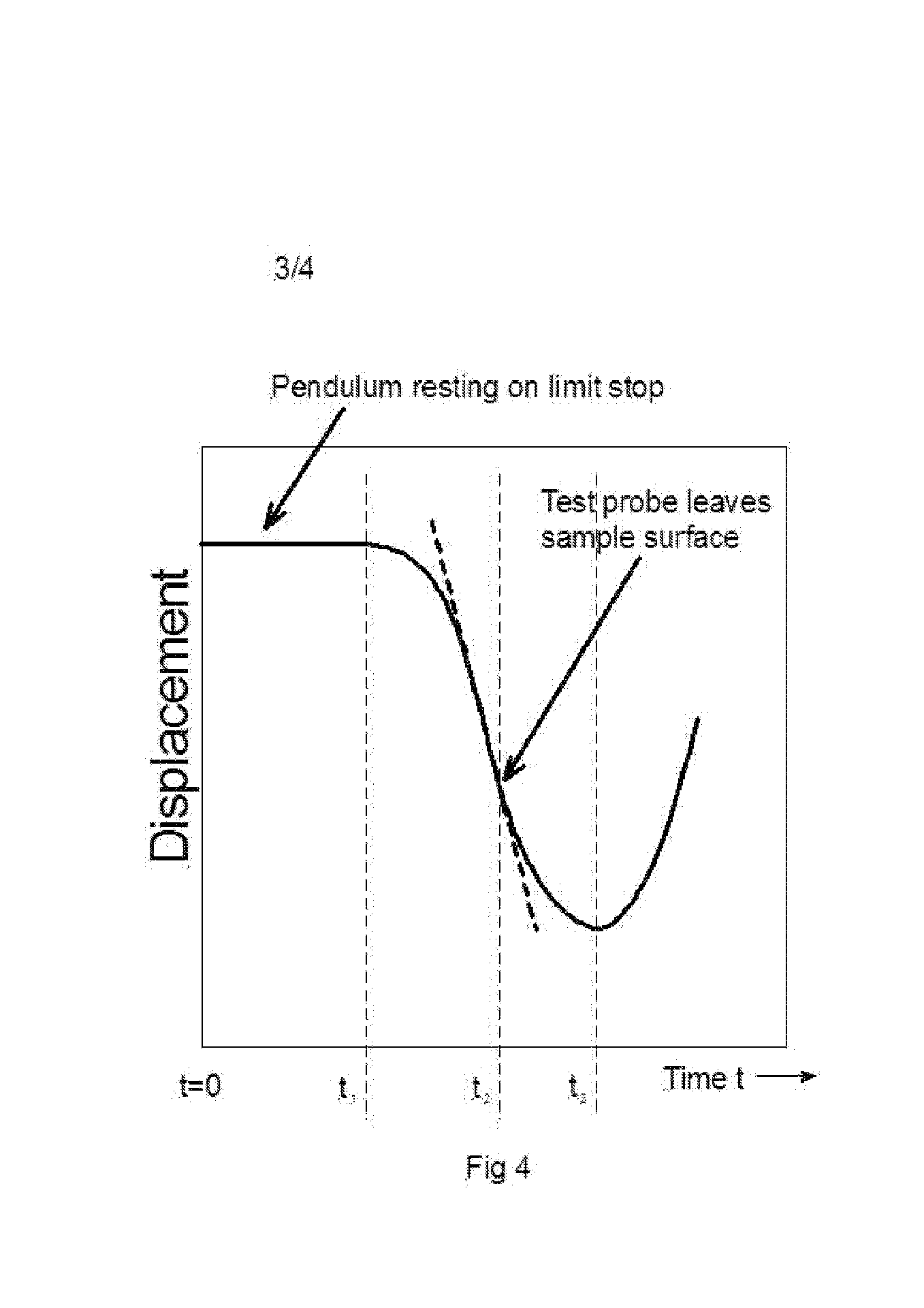

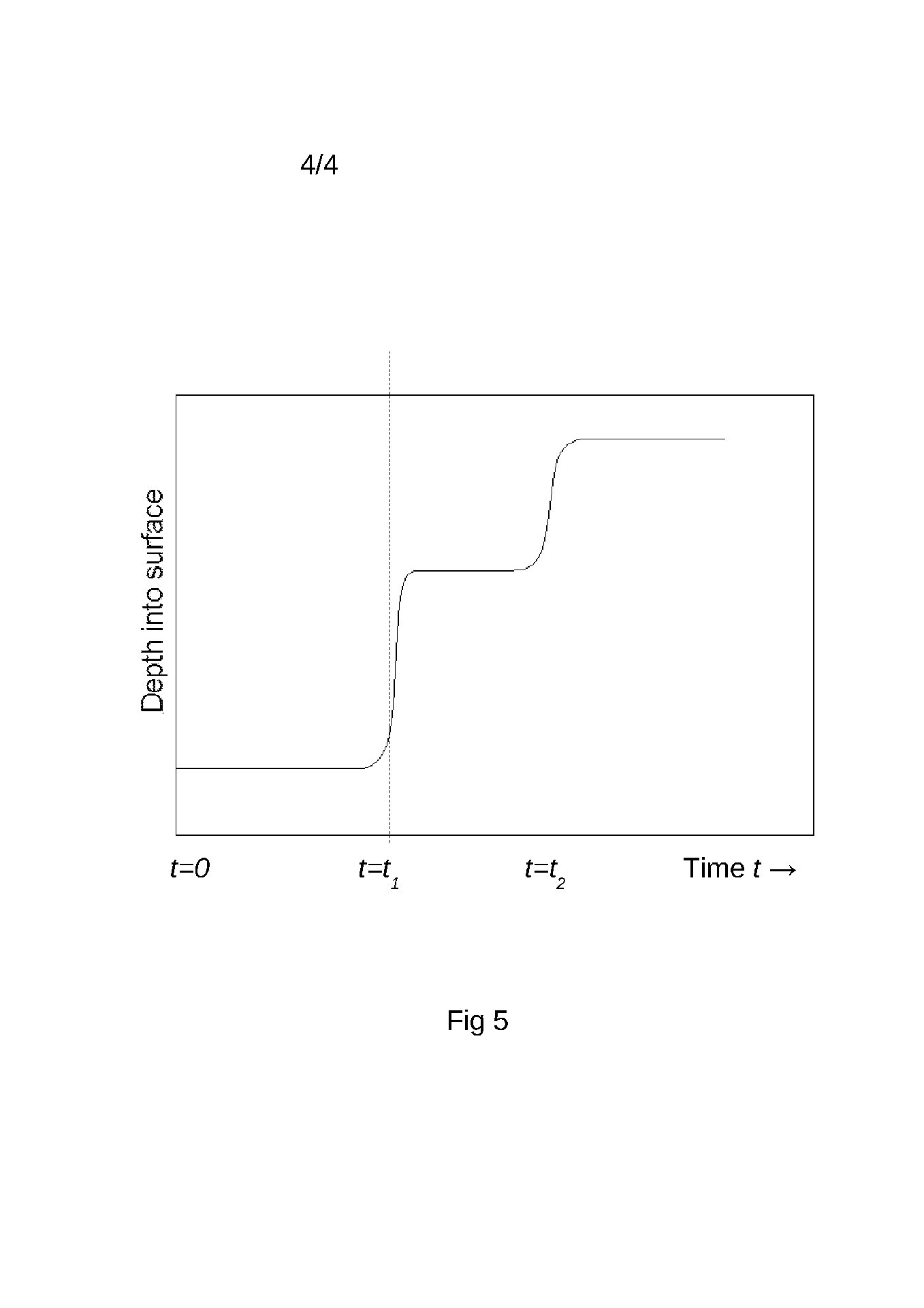

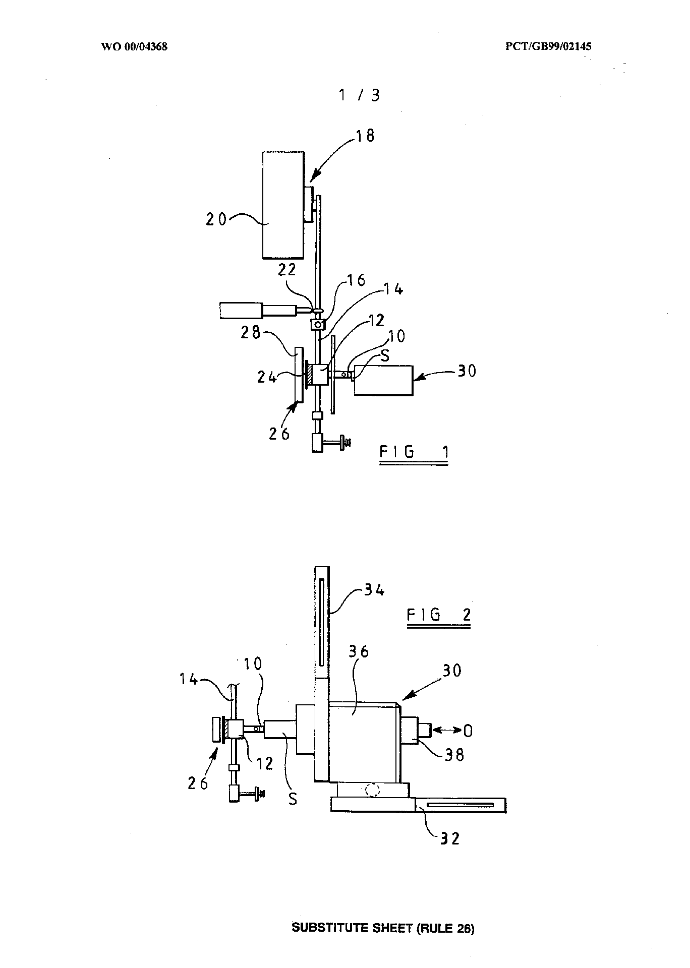

A surface testing equipment comprises a holder for holding a specimen to be tested at a predetermined location; a test probe mounted for recoil movement away from the predetermined location in a predetermined direction; means for urging the test probe towards the predetermined location; means for oscillating either the holder or the test probe so as to cause, in use, repeated impacts between the test probe and a specimen; and means for monitoring the position of the test probe. The testing equipment is capable of being used for surface toughness testing or adhesion testing depending upon the nature of the specimen and the mode of operation of the equipment. One such method comprises the steps of: (a) mounting the specimen in a holder; (b) urging a test probe which is capable of recoil movement away from the specimen into contact with the specimen; (c) oscillating either the specimen holder or the test probe so as to cause repeated impacts between the specimen and the test probe; and (d) monitoring the position of the test probe whilst the specimen or the test probe is being oscillated.

|

|

WO2000004368 - SURFACE TESTING EQUIPMENT AND METHOD

Ref: Ipsum - Online Patent Information and Document Inspection Service

Pendulum impulse impact

Impact – method for measuring surface properties. Apparatus for small-scale impact testing in which high strain rates are produced in a localised small volume. This enables thin film properties to be measured with minimal influence from the underlying substrate.

Application Number : GB0008733.8

Publication Date :

Pendulum Impulse impact – quantitative method for determination of impact energies and determination of dynamic hardness

Ref: Ipsum - Online Patent Information and Document Inspection Service

Variable temperature stage

Variable Temperature Stage – novel design for using continuous depth recording techniques to measure hardness, elastic modulus, scratch resistance and impact resistance at variable temperatures.

Application Number : GB0118182.5

Publication Date :

Pendulum Impulse impact – quantitative method for determination of impact energies and determination of dynamic hardness

Ref: Ipsum - Online Patent Information and Document Inspection Service

Apparatus and method for testing materials

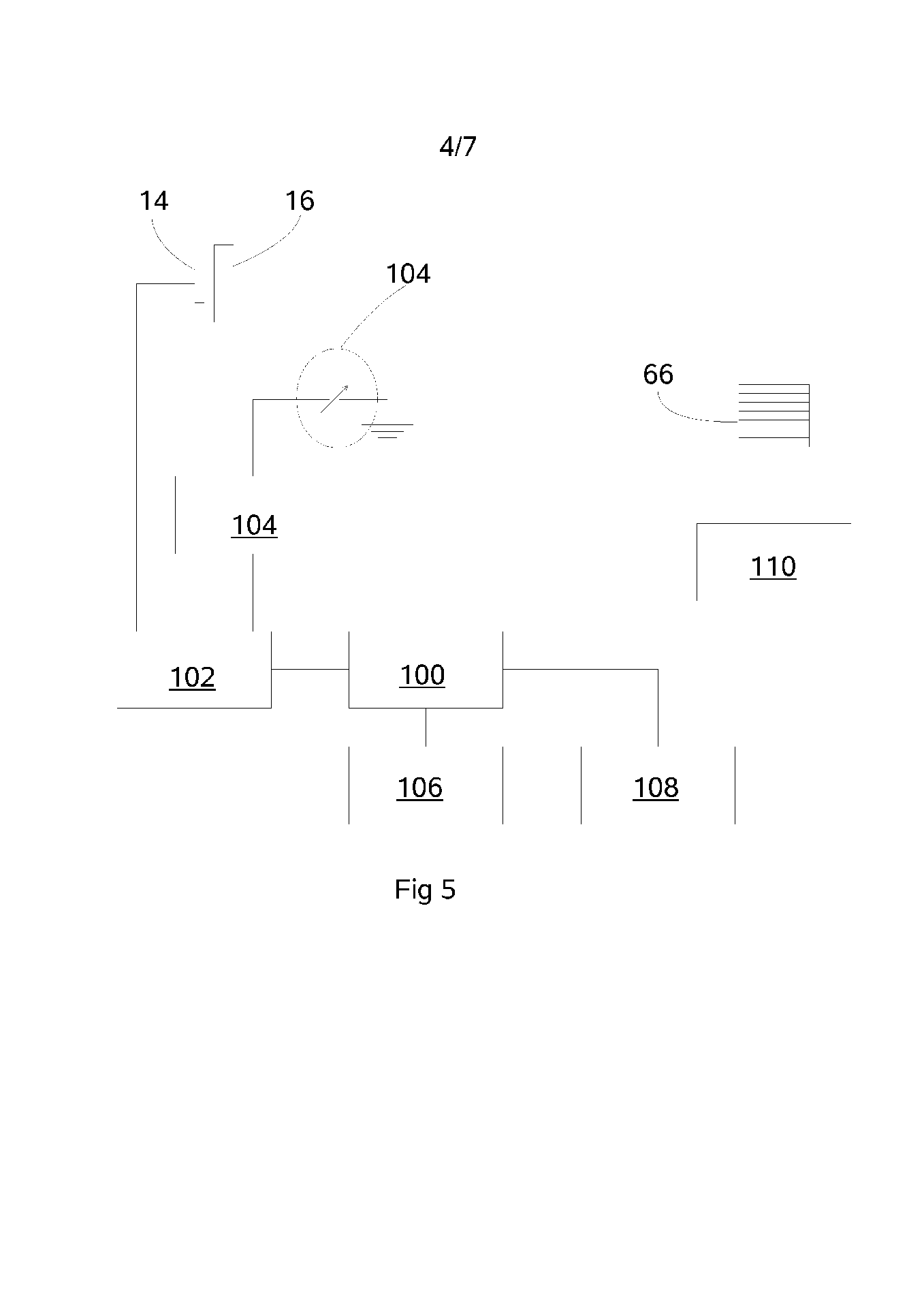

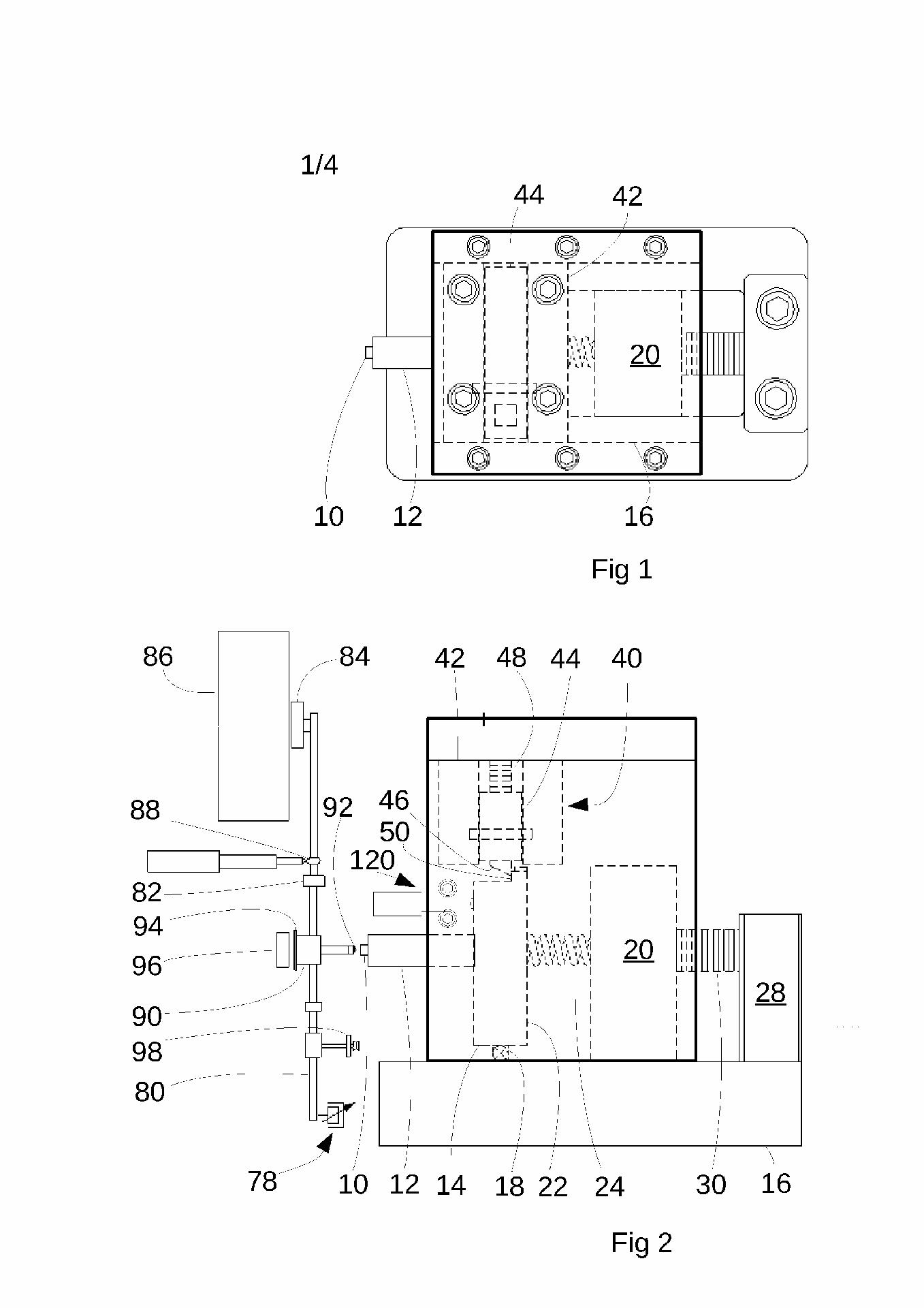

Testing the surface and thin-film mechanical properties of materials using an impact target. Apparatus and method for testing the surface properties, such as the hardness of a sample of material are disclosed. The apparatus includes an impact target 92 supported to have a default location and being resiliently moveable from the default location in a displacement direction. A sample holder 12 is provided to carry a sample 10 to be tested. A drive system 30 drivers the sample 10 towards the target 92 at a known velocity, thereby causing the impact target 92 to be displaced from the default location in the displacement direction. A position measurement system 96 measures movement of the impact target in the displacement direction. Repeated impacts may be used to determine the effect of repeated loading of the sample. The sample holder 12 may be latched by latch assembly 40 against movement toward the impact target 92 while energy is stored in a spring 24, and subsequently unlatched to allow movement towards the impact target 92.

Application Number : GB0920608.7

Publication Date : 01 June 2011

|

|

|

GB2475683 - Apparatus and method for testing materials

Ref: Ipsum - Online Patent Information and Document Inspection Service

Continuous compliance measurement

Continuous compliance measurement

Application Number : GB0008732.0

Publication Date :

Continuous compliance measurement

Ref: Ipsum - Online Patent Information and Document Inspection Service