Friction Testing Solutions for Advanced Materials

Scratch and friction

Technical Notes

NanoTest™ Systems for Accurate Friction and Wear Measurements

Due to the high lateral rigidity, high sensitivity and high stability of the Vantage™ System accurate friction measurements can be performed without artefacts in all the tribological modules providing additional information about deformation and failure mechanisms.

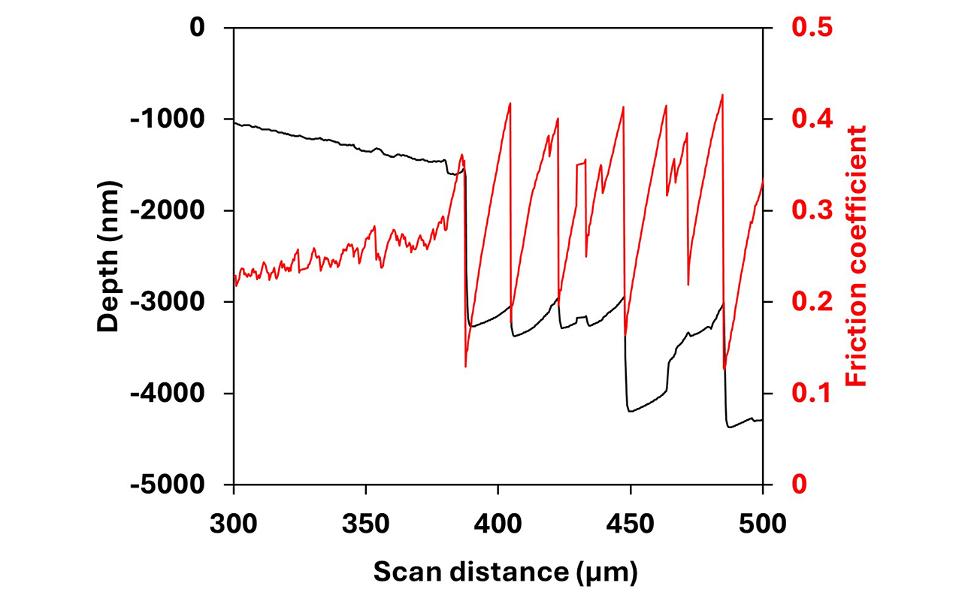

Correlation of friction and depth in ramped nano-scratch test with a 5 µm probe on a 1.1 µm nanocomposite TiN/Si3N4 coating on Si.

Coating failure and chipping of the silicon substrate results in periodic cracking in the scratch track where abrupt increases in depth with friction reduction (due to loss of contact area) are followed by a gradual increase in friction before the next failure event.

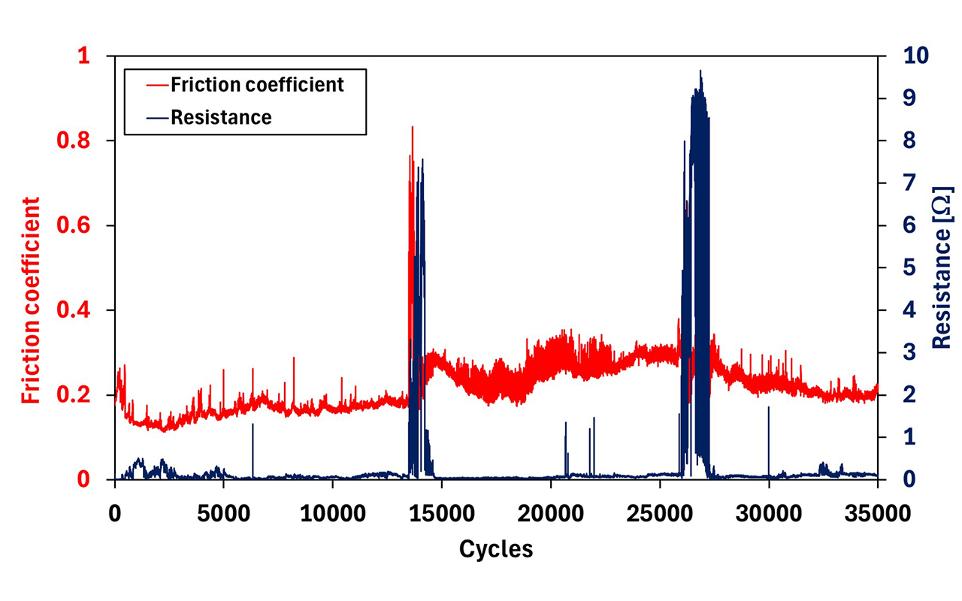

High-cycle reciprocating testing

The NanoTest™ has the stability for high-cycle reciprocating testing of materials for metallic sliding interconnectors. A 35000-cycle test between an Ag alloy pin and Ag alloy disk is shown. Improved detection of the onset of wear and the subsequent failure mechanisms was possible by simultaneously monitoring friction and ECR throughout the 46 hr test.

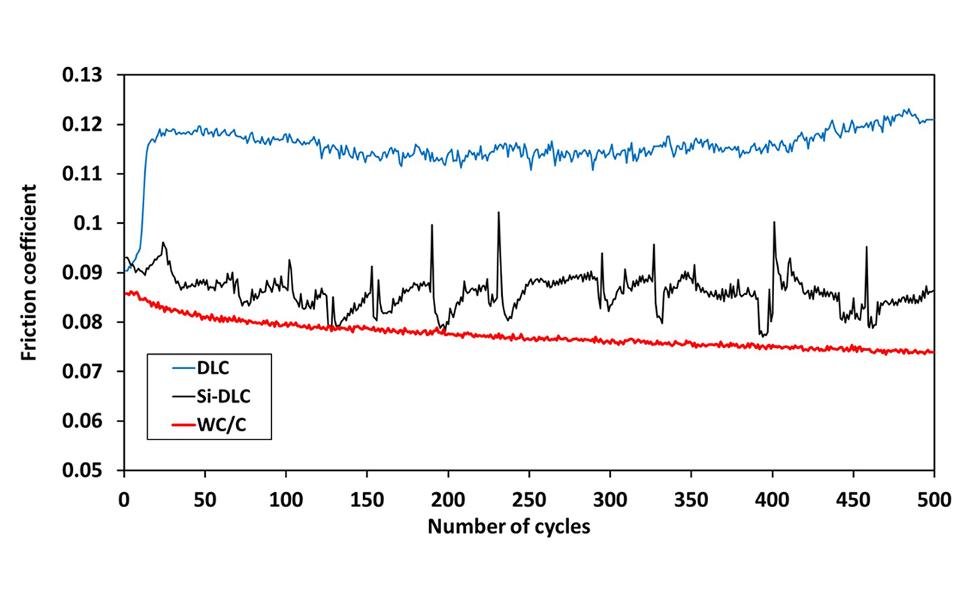

Variation in friction with wear cycles for three hard carbon coatings deposited on hardened tool steel in 500 mN reciprocating tests vs. 25 µm diamond probe.

Although the friction is initially very similar, with continued cycles significant differences emerge. These are due to the relative importance of fracture and deformation on the wear process.

High load testing to 30N

Technical Notes

Nano-fretting

Technical Notes

NanoTriboTest

Technical Notes

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.