Advanced Computational Modelling for Accurate Nanomechanical Testing Analysis

Computational modelling

Technical Notes

Enhance Nanomechanical Testing Accuracy with Advanced Computational Modelling Solutions

A range of modelling modules by the SIO company [1] have been integrated with the NanoTest software. Detailed simulated stress distributions enable NanoTest data to be interpreted more effectively [2-6]. For example, these can be used to determine (i) coating elastic modulus free of substrate influence (ii) elastic modulus at high temperature allowing for the greater creep (iii) interfacial shear strength for quantitative coating-substrate adhesion [4] (iv) residual stress [6].

They provide mechanistic information which can be the key to unlocking exactly where and why coatings systems fail in scratch tests, knowledge which can then be used to design coatings with improved performance.

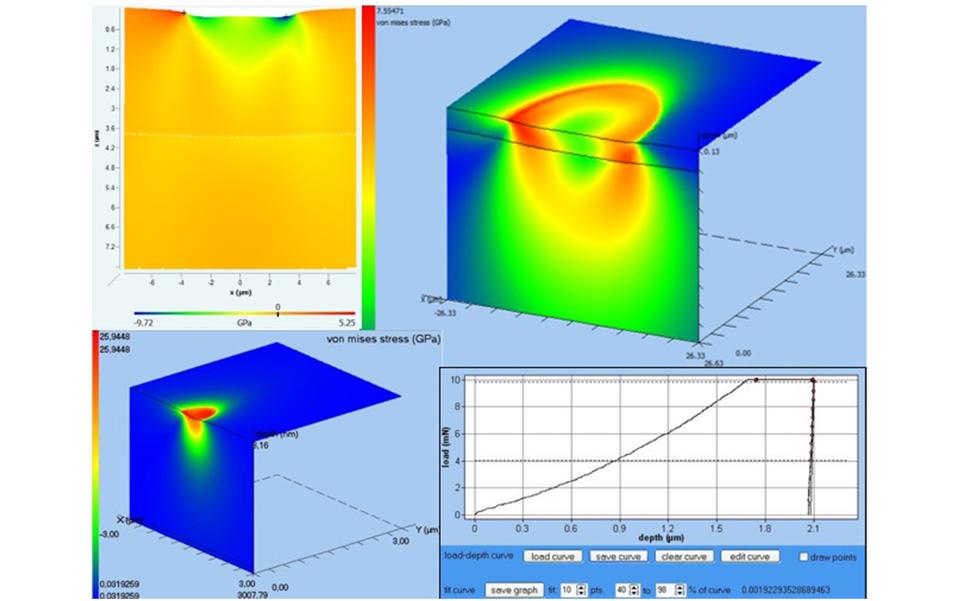

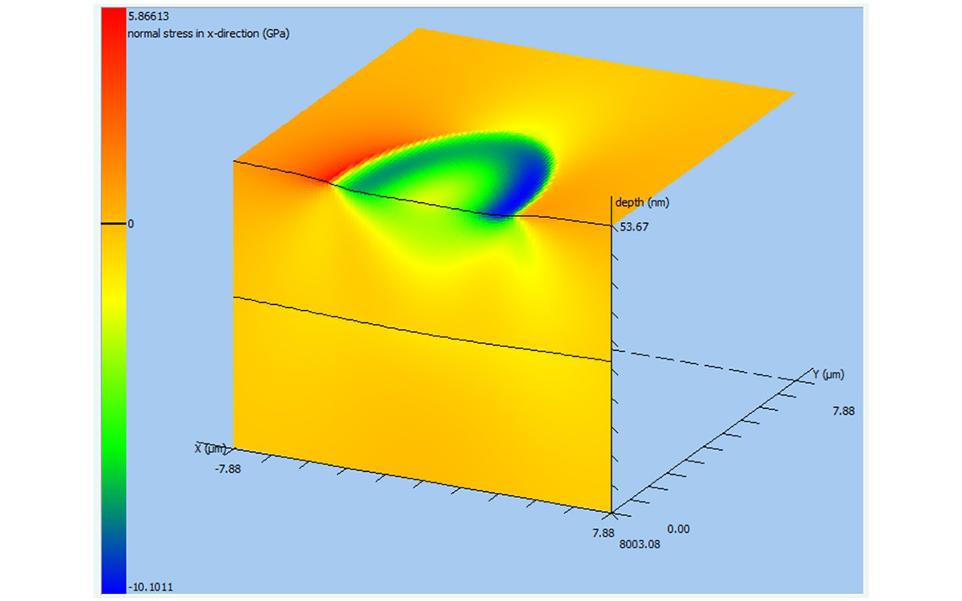

Illustrative examples of the computational options include (a) normal stresses in a micro-scratch test of Si-doped DLC on hardened steel (b) Von Mises stresses in a coating (c) Von Mises stress in the early cycles of nano-fretting of DLC coating (d) fitting creep and unloading curve from a 650 C nanoindentation on P91 steel

During nano-scratch testing high von Mises, normal and shear stresses can develop.

Using NanoTest™ Vantage™ scratch data and mechanical properties from nanoindentation as input to the model the integrated SIO software determines these stresses.

Nano-scratch of Si-doped DLC on hardened steel. At the cracking critical load high tensile stresses develop at the surface in a ring behind the contact, at the point where microscopy shows cracking.

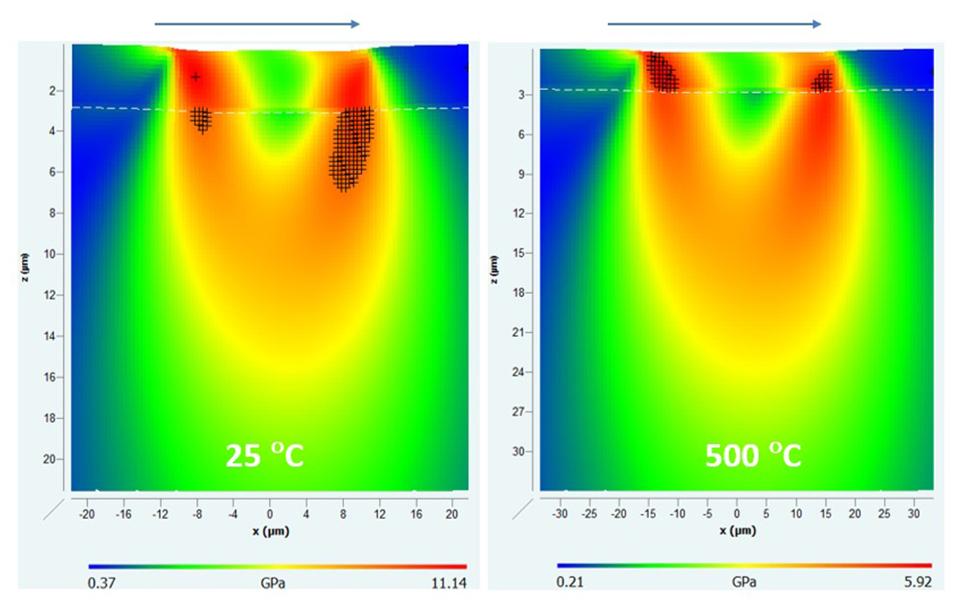

Simulations can reveal exactly how changing test temperature can alter the stresses developed in the scratch test.

The figure shows von Mises stress distributions at failure when scratching a hard AlTiN coating on a cemented carbide cutting tool at 25 and 500 C.

Increasing temperature alters where the coating system is overstressed (shown by the hashed regions) and changes the failure mechanism.

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.

References:

1. N Schwarzer, Ch22, pp513-560 in Applied Nanoindentation in Advanced Materials, Wiley, Eds. Dr A Tiwari and S. Natarajan, 2017.

2. BD Beake et al, Surf Coat Technol, 309 (2017) 671.

3. BD Beake et al, IJRMHM 69 (2017) 215-226.

4. S Chowdhury et al, Coatings 8 (2018) 59 (15pp).

5. TW Liskiewicz et al, Surf Coat Technol 237 (2013) 212.

6. S Vogt et al, Production Engineering 13 (2019) 133.

Nanoindentation

Technical Notes

Scratch and friction

Technical Notes