DLC Coatings

Advanced Protection for High-Performance Applications

Nano-impact testing of DLC coatings for

automotive engine applications

Brochure

Enhanced Durability & Performance with Advanced DLC Coatings

What Are DLC Coatings?

Diamond-Like Carbon (DLC) coatings are advanced protective layers engineered to enhance the durability, wear resistance, and efficiency of components operating under extreme conditions. These coatings combine the properties of natural diamond—such as hardness and low friction—with the flexibility and adaptability of amorphous carbon structures. As a result, DLC coatings are widely used across industries, particularly in automotive, aerospace, and precision manufacturing applications.

Why Choose DLC Coatings?

DLC coatings offer exceptional friction reduction, making them ideal for automotive engine components like tappets, pistons, and fuel injectors. As modern engines become more compact and efficient—incorporating features like turbocharging and low-viscosity lubricants—many components are exposed to severe operating conditions. Without proper protection, these parts suffer from wear, fatigue, and performance degradation over time.

DLC coatings are specifically designed to:

- Reduce friction and enhance fuel efficiency

- Minimize wear and extend component lifespan

- Improve resistance to impact and fatigue failure

- Provide superior lubrication performance under boundary conditions

Image info: The Nano-impact test involves multiple true high strain rate impacts on the sample surface

-

Nano-Impact Testing for DLC Coatings

To ensure DLC coatings can withstand real-world mechanical stresses, Micro Materials employs patented nano-impact testing—a high-strain rate technique that mimics the severe dynamic loading conditions found in automotive engines, aerospace applications, and high-speed cutting tools.

Unlike conventional nanoindentation tests, which only assess initial crack resistance, nano-impact testing evaluates coating durability under continuous stress cycles. This provides valuable insights into:

- Toughness – The ability to resist crack initiation under impact.

- Damage Tolerance – The ability to slow down or prevent crack propagation.

- Fatigue Resistance – The longevity of the coating under repetitive high-load conditions.

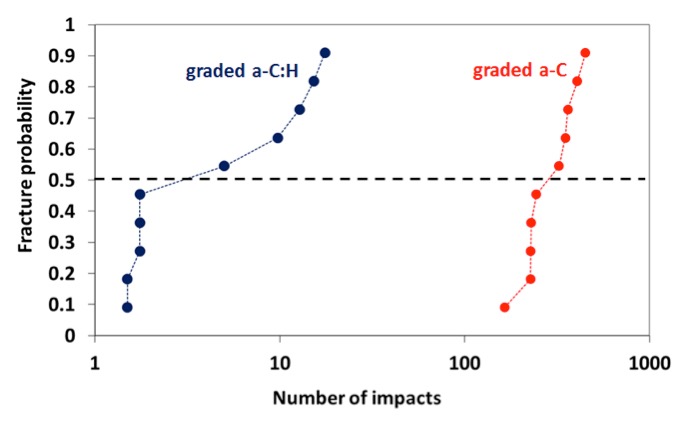

Image info: Cumulative probability distribution of time-to-failure in 5 mN tests on graded coatings

Key Findings from Our DLC Coating Research

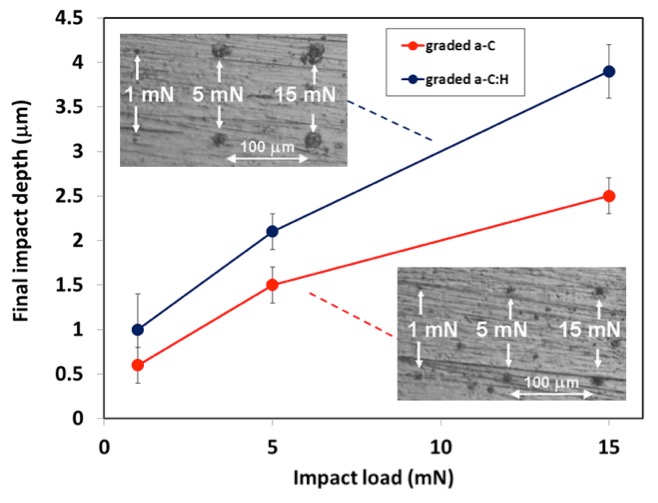

Our studies on various DLC coatings applied to M42 tool steel revealed critical differences in performance:

- Graded a-C (Hydrogen-Free DLC) coatings exhibit higher impact resistance and superior durability under severe loading conditions.

- Hydrogenated DLC (a-C:H) coatings demonstrate higher hardness but reduced impact tolerance, making them more susceptible to brittle fracture.

- Compositional grading within DLC coatings enhances stress transfer and plasticity, improving overall resilience under dynamic conditions.

Image info: Final impact depth after 450 impacts at 1,5 and 15 mN on graded a-C:H and a-C

Innovative DLC Coating Solutions for the Future

At Micro Materials, we continue to push the boundaries of material science by optimizing DLC coatings for real-world applications. Our state-of-the-art nano-impact testing, combined with advanced coating design strategies, ensures that components in high-performance industries achieve the best possible protection.

Discover how DLC coatings can improve your application’s performance. Contact us today to learn more.

High load testing to 30N

Technical Notes

Nano-fretting

Technical Notes

NanoTriboTest

Technical Notes

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.