The 10% Rule in Nanoindentation: Ensuring Accurate Thin Film Measurements

High temperature publications 2024

Application Notes

What is the 10% Rule in Nanoindentation? - Micro Material UK

The 10% rule in nanoindentation is a guideline used to minimize the influence of the substrate when measuring the mechanical properties of thin films or coatings. It states that:

The indentation depth should not exceed 10% of the film thickness to ensure that the measured hardness and elastic modulus primarily reflect the film's properties rather than those of the underlying substrate.

Why is the 10% Rule Important?

- Avoids Substrate Effect: If the indentation is too deep, the measured values will be influenced by the substrate, leading to inaccurate results.

- Ensures Reliable Data: By keeping the penetration depth shallow, the mechanical properties of the thin film or coating can be measured more accurately.

- Common Practice in Material Testing: Researchers and engineers use this rule when testing coatings on metals, ceramics, and polymers to get reliable mechanical property data.

For immediate assistance, you can reach us by phone or email. Our team is always happy to answer any queries you have, big or small. Check our contact details below:

- Phone: +441978261615

- Email: info@micromaterials.co.uk

- Office Address: Willow House • Yale Business Village • Ellice Way • Wrexham • LL13 7YL • United Kingdom

- Business Hours : We operate from 08:30am to 05:00pm Monday through Friday, and we aim to respond to all messages within 24 hours.

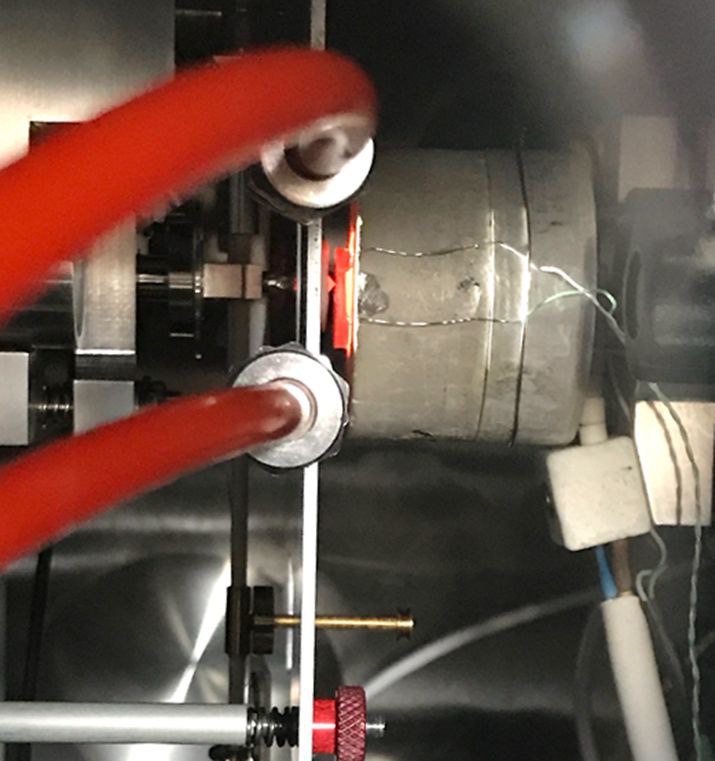

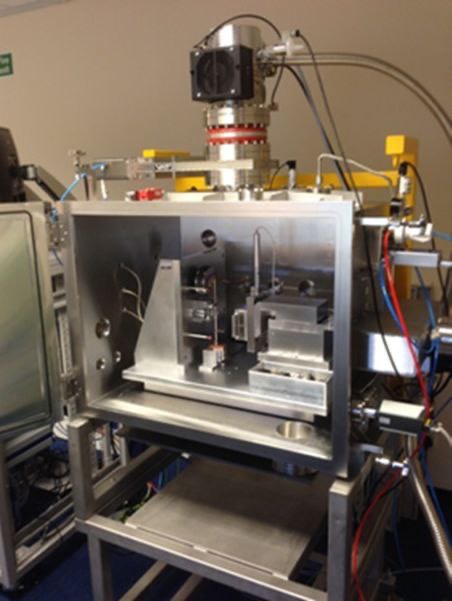

Inside a NanoTest Xtreme nanomechanical test system, capable of testing at high temperatures, upto and exceeding 1000 °C , under high vacuum conditions

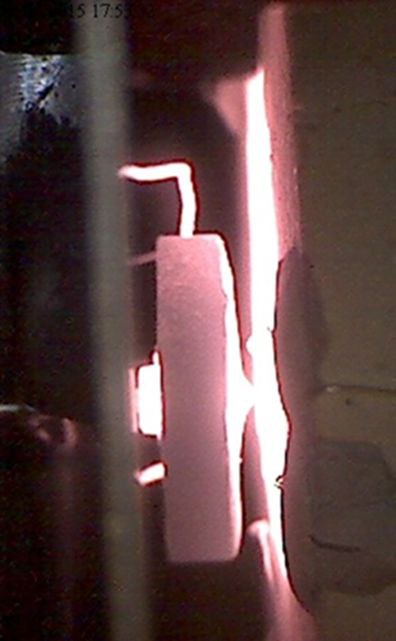

Image showing high temperature nanoindentation testing at temperatures over 900 °C using the NanoText Xtreme instrument supplied by Micro Materials Ltd

Image taken by Adrian Harris of Micro Materials Ltd, showing localised heating at 950 °C on an Xtreme system

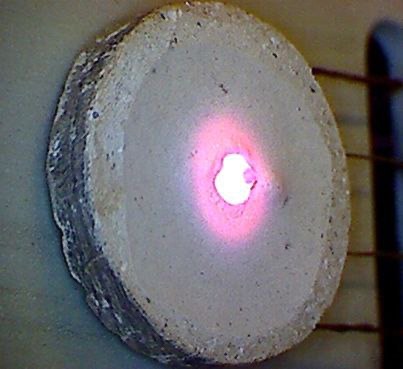

Image taken by Andrew Bird (Micro Materials Ltd), showing localised heating at

750 °C on an Xtreme system in use at the University of Oxford

Nanomechanical testing to 1000 °C

Application Notes

High temperature micro-scratch and impact

Technical Notes

High temperature creep resistance

Application Notes

Nuclear materials

Application Notes

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.