What is cryogenics used for?

Cold stage

Technical Notes

What is cryogenics used for?

Cryogenics is used in various industries to improve material properties, enhance performance, and enable scientific advancements. Some key applications include:

1. Industrial & Manufacturing:

- Cryogenic Treatment of Metals & Tools: Enhances durability, wear resistance, and toughness in cutting tools, engine components, and industrial machinery.

- Superconductors: Used in high-tech applications like MRI machines and particle accelerators.

2. Aerospace & Automotive:

- Cryogenic Fuels: Liquid hydrogen and oxygen are used as rocket propellants.

- Metallurgical Enhancement: Reduces internal stresses in engine parts, improving lifespan and efficiency.

3. Medical & Biological Sciences:

- Cryopreservation: Used for preserving biological samples, organs, and even human tissues.

- Medical Imaging: Liquid helium cools MRI scanners for high-resolution imaging.

4. Food & Beverage Industry:

- Cryogenic Freezing: Quick-freezing food products to maintain texture, flavor, and freshness.

5. Electronics & Computing:

- Quantum Computing: Super-cooling materials to near absolute zero for faster, more efficient computing.

Low-temperature creep behavior has been extensively studied across various materials. Here are some notable publications:

Low-Temperature Creep Plasticity

This review by M.E. Kassner, K.K. Smith, and C.S. Campbell, published in the Journal of Materials Science in 2015, examines the mechanisms and phenomenological relationships describing primary creep in pure metals and alloys at low temperatures.

Low-Temperature Creep in Pure Metals and Alloys

In this 2015 study, M.E. Kassner, K.K. Smith, and C.S. Campbell analyze the phenomenological relationships that describe primary creep in pure metals and alloys at low temperatures, focusing on the controversy between power-law and logarithmic descriptions.

Low-Temperature Creep Behaviour of Pipeline Steels

This 2009 research by M.S.J. Hashmi and colleagues, published in Materials Science and Technology, investigates the room temperature creep behavior of various grades of pipeline steels, including X-52, X-70, X-80, and X-100.

Effect of Low-Temperature Annealing on Creep Properties of AlSi10Mg Alloy Produced by Additive Manufacturing: Experiments and Modeling

In this 2021 study, Chiara Paoletti and colleagues, published in Metals, examine the effects of post-processing annealing at 225°C for 2 hours on the creep properties of AlSi10Mg alloy produced by additive manufacturing.

Fast Low-Temperature Irradiation Creep Driven by Athermal Defect Dynamics

This 2024 study by Alexander Feichtmayer and colleagues, published on arXiv, observes and models a non-linear high-dose radiation-mediated microstructure evolution effect that facilitates fast stress relaxation in the low-temperature limit.

For immediate assistance, you can reach us by phone or email. Our team is always happy to answer any queries you have, big or small. Check our contact details below:

- Phone: +441978261615

- Email: info@micromaterials.co.uk

- Office Address: Willow House • Yale Business Village • Ellice Way • Wrexham • LL13 7YL • United Kingdom

- Business Hours : We operate from 08:30am to 05:00pm Monday through Friday, and we aim to respond to all messages within 24 hours.

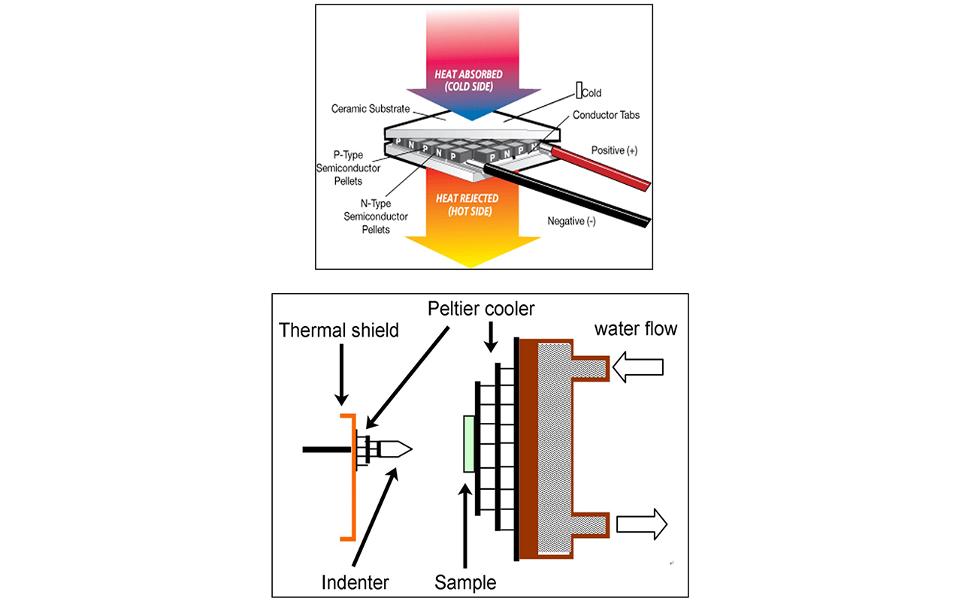

The cold stage from Micro Materials allows the user to perform nanoindentation, nano-scratch & wear and nano-impact tests with the indenter and sample at sub-ambient temperatures; down to -20 °C on the NanoTest™ Vantage™, and -40 °C on the NanoTest™ Xtreme™

The cold stage uses precise Peltier cooling to cool both the sample stage and indenter to the required test temperature. Proprietary techniques then ensure isothermal contact between the indenter and the sample before the test starts.

Experiments take place in a nitrogen purged atmosphere (Vantage™) or high vacuum (Xtreme™) to stop the formation of ice crystals in the test region. Testing can then be performed at any temperature from room temperature down to -20 ºC (Vantage™) or -40 ºC (Xtreme™).

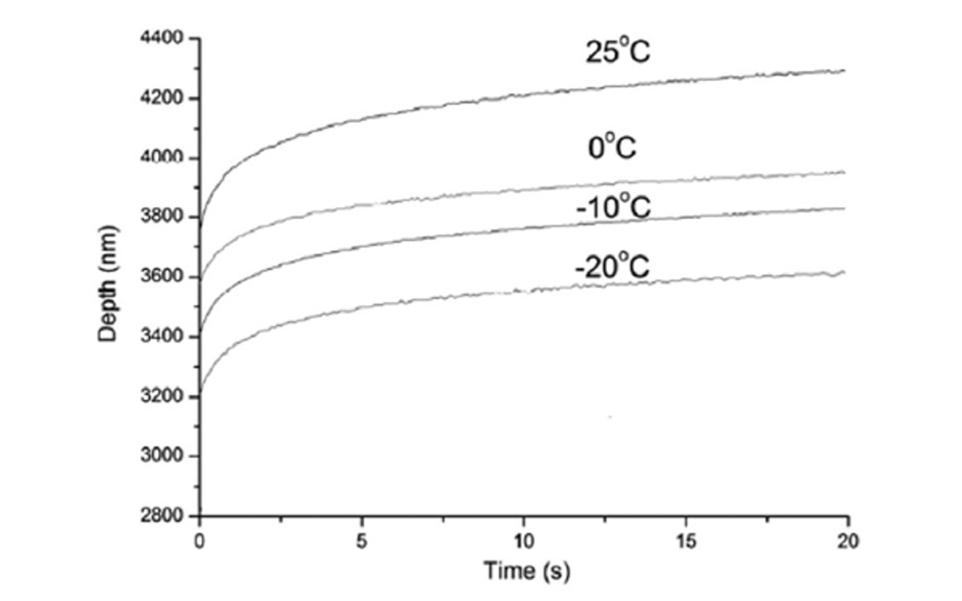

A key area of interest in polymer research is the effect of low temperatures on the creep behaviour of polymer films.

The stability of the NanoTest™ at sub-ambient temperatures allows direct assessment of the creep behaviour even at the lowest temperatures.

The example shown here demonstrates difference in creep behaviour of a polymeric sample – as the temperature is lowered, the creep rate reduces due to the reduction in viscoelastic behaviour of the sample.

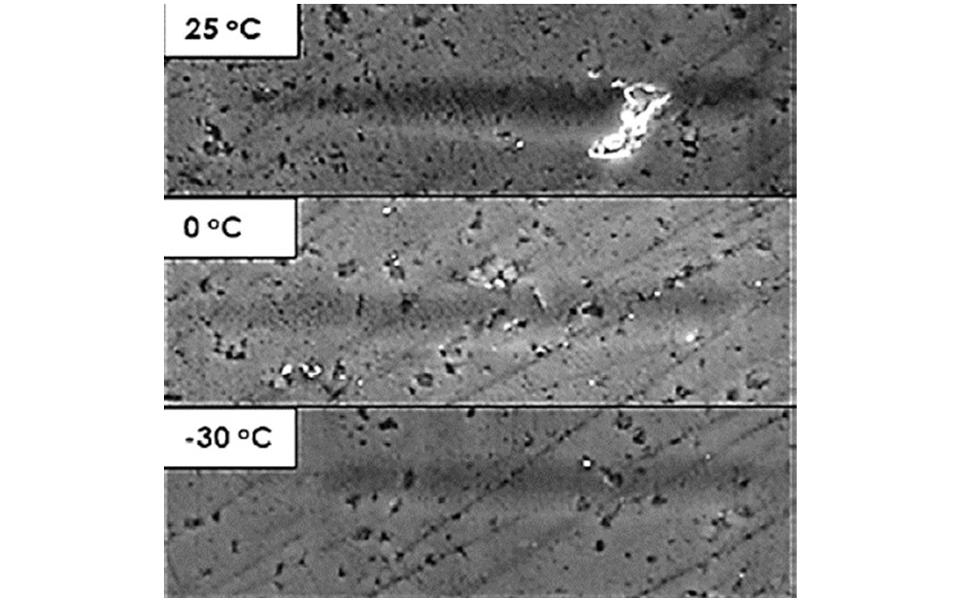

It is also possible to directly assess material wear behaviour by combining the cold stage and scratch test capabilities of the NanoTest™. This has been done in the example shown where ramped load scratch tests have been performed on a composite DLC coating at different temperatures.

Interestingly, the volume of material removed from the surface reduces as the sample is cooled. The wear track is significantly shallower at sub-ambient temperatures than at room temperature. The coating is also more resistant to cracking at lower temperatures.

Nanoindentation

Technical Notes

Explore More

To further enhance your experience and understanding, we invite you to check out the following pages on our website that we believe are essential to your journey with us:

- High-Temperature Nanoindentation Testing for Advanced Material Characterization

- Advanced Nano Scratch and Wear Testing for Coatings and Materials

- Nano-Impact Testing for Advanced Material Performance in High-Stress Applications

These pages offer valuable insights and resources to help you achieve your goals.