Acoustic Emission

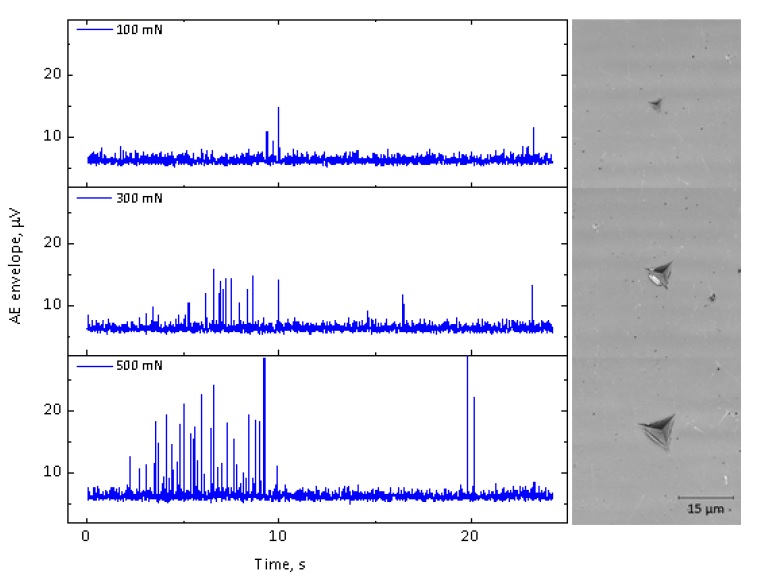

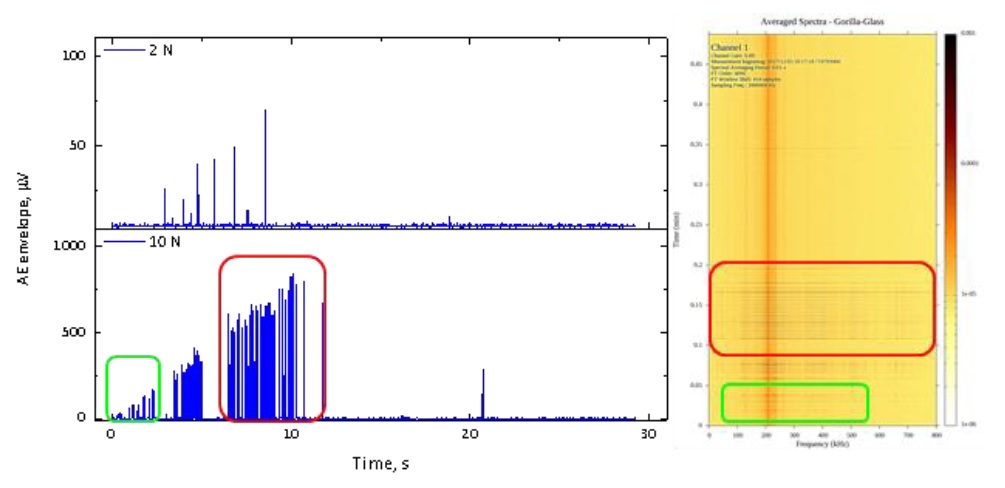

High frequency Acoustic Emission (AE) monitoring during nanomechanical tests such as nanoindentation, nano-scratch, nano-impact, micro-pillar compression and micro-cantilever bending provides valuable additional information to improve our understanding of material behaviour at the nano-scale.

Acoustic waves emitted during mechanical tests at the nano and micro scale are a rich source of information about the deformation behaviour (e.g. initiation and propagation of cracks, plastic instabilities, etc.) that may be otherwise inaccessible.

Benefits of Acoustic Emission on the NanoTest:

- Improved accuracy in scratch test critical load

- Uncover cracking events in nanoindentation where load-depth profiles are smooth

- Differentiate between slip and fracture in impact

- Study yield behaviour

- Differentiate between different cracking processes

- Improved understanding of nanotribological tests

How does it work?

Acoustic emission activity is continuously recorded and analyzed throughout the tests with a high-sensitivity ZEDO system (Dakel, Czech Republic) with a high dynamic range and sampling frequency of 10 MHz. This specification allows the study of very weak as well as strong AE events at nanosecond scale in a broad frequency range up to 2 MHz.

Direct synchronization with the NanoTest means the depth-load-time records can be related to AE signals. During the test the samples are mounted on the low noise/high-sensitivity AE sample holders that contain dedicated structured piezo-element and inbuilt pre-amplifiers. The AE hit waveform sampled at MHz frequency is described by several characteristics that provide different insights into the origin of the detected signal.